Air Release Valve solves Fungicide Spray control problems

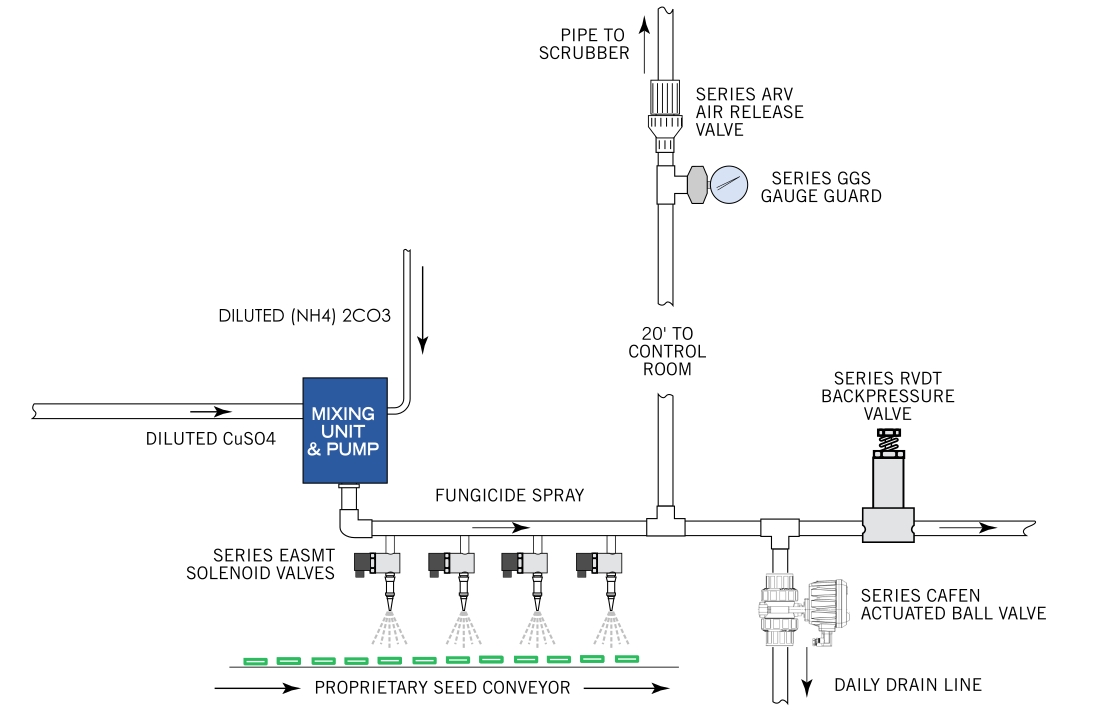

A proprietary seed grower uses a solution of copper sulphate (CuSO4) and ammonium carbonate [NH4]2CO3 as a product fungicide.

The system relies on a Series RVDT Teflon diaphragm Backpressure Valve to maintain a set pressure to the spray heads, which is verified by a pressure gauge located in a control room above the system. The gauge is isolated from the solution with a Series GGS Gauge Guard to prevent chemical attack of the metal Bourdon tube in the gauge.

The system is shut down and drained daily after the last batch is treated. The drain pipe is located upstream of the Backpressure Valve, and is opened and closed via Series CAFEN Actuated Ball Valve.

A problem arose during morning startup, when a large column of air would be trapped and pressurized in the standpipe used for the Gauge Guard and pressure gauge in the control room. The pressurized liquid usually compressed the air so the pressure readings were often accurate, but not always. The air pocket caused much more significant problems by creating entrained air while the system was running, resulting in uneven application of the spray and damage to the spray heads. It also created a potential safety hazard, as most thermoplastic piping is not designed for compressed air and has the potential for catastrophic failure.

The operator resisted a suggestion to remove the standpipe, so the Plast-O-Matic engineering team recommended installation of an automatic Air Release Valve on a piping tee above the Gauge Guard. In the morning when the system is restarted, incoming liquid forces air up and out through the ARV, eliminating the compressed air pocket. As the liquid rises it fills the base of the Gauge Guard for greater accuracy. When it reaches the ARV it lifts the internal float and automatically closes the valve. Because the upper vent has the potential to spit residual liquid or vapor, Plast-O-Matic recommended that it be piped to a safe collection point – in this case a scrubber. When the Ball Valve is opened at the end of the day, liquid drops and the ARV automatically opens and assists the draining process.

All valves used in the process feature isolated metals to eliminate corrosion and release of metal particulate into the chemical solution.