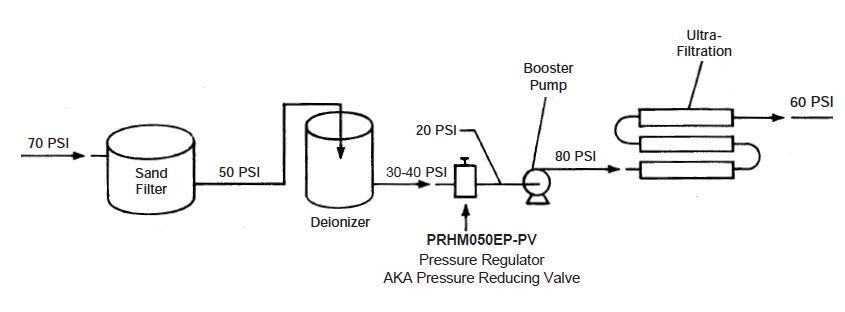

Reducing valve provides constant inlet pressure for booster pump

During the water treatment/purification process at a small municipal plant, it passes through numerous pieces of equipment including sand filters, deionizers, reverse osmosis, etc.

As the water flows from stage to stage its pressure drops and must be increased at some point for the next piece of equipment to work properly. Booster pumps are used for this purpose – taking a

lower pressure flow and increasing it to a predetermined higher pressure. However, these pumps work most efficiently if their suction pressure is constant; unfortunately in this application the successive downstream pressure fluctuated depending on the equipment. The installation of a Series PRHM Pressure Regulator on the suction feed provides a constant reduced pressure to the pump, regardless of varying line pressures into the Regulator.

Pressure Regulators, also known as Pressure Reducing Valves, automatically convert varying or excessive inlet pressures to a desired constant lower downstream pressure.

Uses include…

• Prevent overpressure conditions to downstream equipment such as filters, sensitive tools, etc.

• Convert excessive or wildly fluctuating upstream pressure to a constant predetermined downstream pressure.

• Control pressure differential (Delta P) across downstream system equipment (known as a Differential Regulator).

• Regulate to the correct pressure range so that a flow system or piece of equipment can operate safely and effectively.

How it functions:

Common misconceptions about Pressure Regulators

A pressure regulator cannot increase pressure. If upstream pressure drops below the set point, downstream pressure will also…a pressure regulator does not function like a pump. Secondly, Pressure regulators will not function as backpressure regulators. Pressure regulators are normally-open valves that are used to prevent downstream pressure from exceeding a predetermined set point. In some applications this is known as forward pressure control.

A common misapplication is to use a Pressure Regulator to regulate flow. While they affect flow rates, “pressure regulators” are designed to control pressure, not flow. To assure specific flow rates, Plast-O-Matic offers an extremely accurate and cost-effective flow control valve.

For more information and product specifications, please click here.