In the world of industrial applications, the choice of valves can significantly impact system efficiency and reliability. Among the various types, the ball valve stands out for its superior performance in flow control and tight sealing capabilities. This blog delves into the comprehensive technical specifications of the best ball valves available on the market, specifically highlighting those manufactured by top-quality factories in China.

As we explore the key features and advantages of these robust components, readers will gain insights into why ball valves are essential for a myriad of applications, from oil and gas to water treatment. Whether you are an engineer, a procurement specialist, or simply interested in improving your system’s operation, understanding the intricacies of ball valves will be vital for making informed decisions.

Join us as we uncover what makes these valves a preferred choice in the industry.

As we explore the key features and advantages of these robust components, readers will gain insights into why ball valves are essential for a myriad of applications, from oil and gas to water treatment. Whether you are an engineer, a procurement specialist, or simply interested in improving your system’s operation, understanding the intricacies of ball valves will be vital for making informed decisions.

Join us as we uncover what makes these valves a preferred choice in the industry.

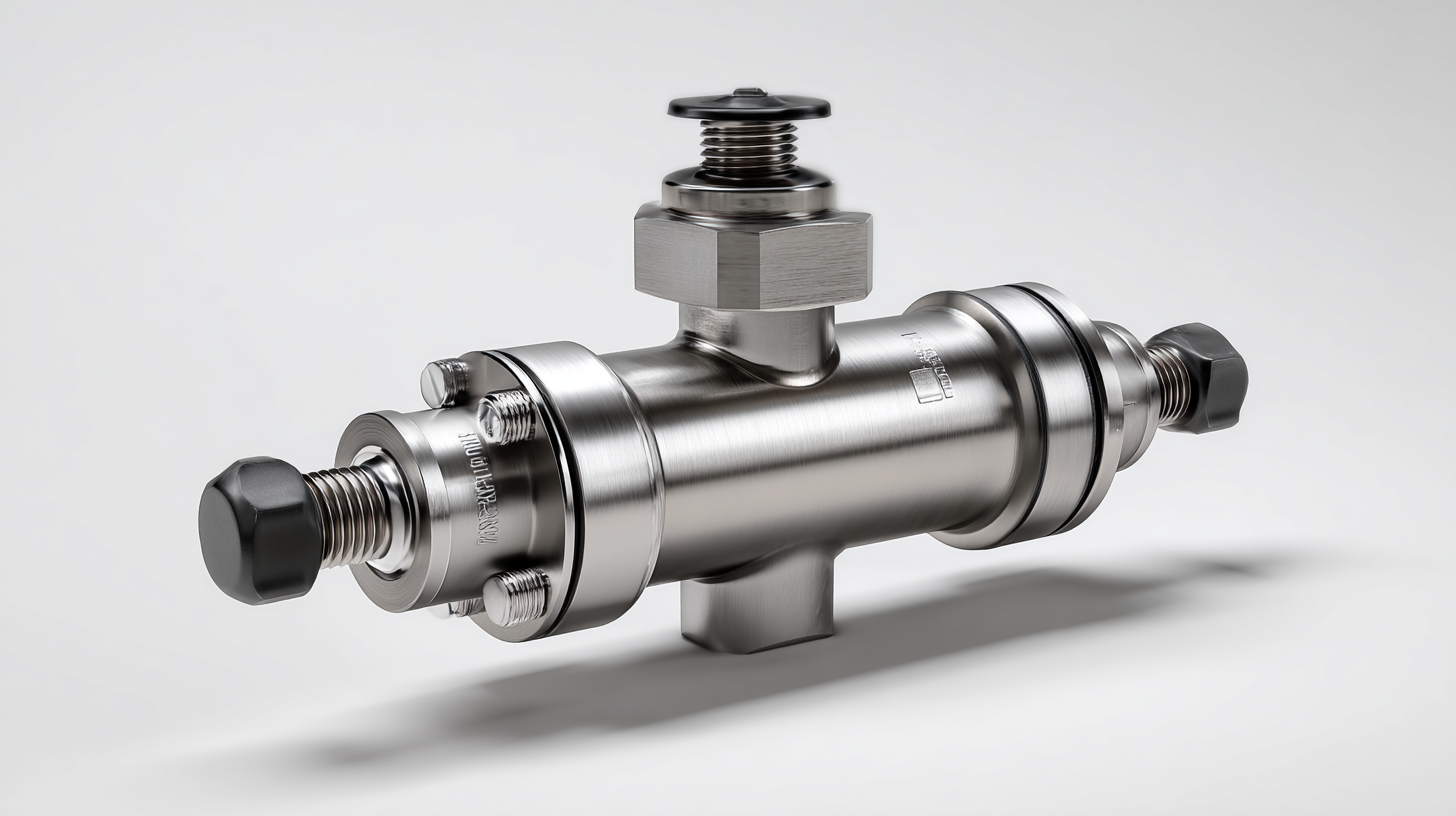

When it comes to selecting the best ball valve in today’s market, several key features stand out that define quality and performance. First and foremost, the material construction of the valve plays a crucial role in its efficiency and durability. High-quality ball valves are typically made from stainless steel or brass, ensuring resistance to corrosion and high pressures. Additionally, the valve's seat material, often PTFE or modified PTFE, not only enhances sealing capabilities but also increases longevity, making it ideal for a range of applications in both commercial and industrial settings.

Another essential characteristic is the valve's design, particularly the type of ball (full-port vs. standard-port) and the flow control mechanism used. Full-port ball valves offer unobstructed flow, minimizing pressure drops and allowing for greater flow rates, which is especially beneficial in systems that carry fluids with varying viscosities. Moreover, features like an ISO mounting pad for actuators and ergonomic handles contribute to ease of use and compatibility with automation solutions. Such thoughtful engineering ensures that the best ball valves not only meet stringent operational standards but also enhance overall system performance.

This chart illustrates the performance metrics of the highest-rated ball valves in terms of flow capacity, durability, and pressure rating. Analyzing these specifications helps in understanding the best options available on the market.

Ball valves are essential components in various industries due to their reliability and efficiency in regulating flow. Understanding the different types of ball valves is crucial for selecting the right one for your application. The most common types include floating ball valves, trunnion-mounted ball valves, and quarter-turn ball valves, each designed for specific operational requirements. According to a market research report by Mordor Intelligence, the global ball valve market is projected to grow by over 5% annually through 2025, highlighting the increasing reliance on these devices in sectors like oil and gas, water treatment, and chemical processing.

When selecting a ball valve, consider the operational environment. Floating ball valves are ideal for low-pressure applications, while trunnion-mounted ball valves are better suited for high-pressure requirements due to their robust design. Additionally, materials such as stainless steel and carbon steel should be chosen based on corrosion resistance and temperature tolerances.

**Tip:** Always check the valve's pressure rating and temperature range against your system requirements to ensure optimal performance and longevity. Additionally, consider the maintenance needs of the valve. Periodic inspections can help prevent leaks and ensure that the ball valve operates smoothly throughout its lifecycle.

When selecting a high-quality ball valve, the materials used in its construction are paramount. Manufacturers typically utilize materials such as stainless steel, brass, and PVC, each offering distinct advantages depending on the application. Stainless steel is renowned for its corrosion resistance and durability, making it ideal for harsh environments. Conversely, brass valves are often chosen for their robustness and suitability in moderate pressure systems. PVC, while less durable than metal options, is lightweight and resistant to chemicals, making it perfect for specific industrial applications.

Tip: Always consider the environment in which the valve will operate. For instance, if the valve is meant for outdoor use in a corrosive atmosphere, stainless steel or a high-grade plastic would be preferable to prevent premature failure.

Another critical factor is the valve's internal components, such as the ball and seats. The ball is generally made of the same material as the valve body, ensuring a uniform lifespan and performance. Seats, on the other hand, are often crafted from materials like PTFE or rubber to provide a reliable seal and reduce friction. This combination is essential for achieving the desired flow control and minimizing leakage.

Tip: Regular maintenance can prolong the life of your ball valve. Inspect and clean the seals periodically to ensure optimal functionality and prevent any blockages or leaks.

When selecting a premium ball valve, it is crucial to consider essential standards and certifications that ensure product quality and reliability. Many of the best ball valves on the market comply with international standards such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO). These certifications provide assurance that the valves have undergone rigorous testing for performance, safety, and durability.

Another important certification to look for is the American Society of Mechanical Engineers (ASME) stamp, which indicates that the valve meets stringent engineering standards. Additionally, valves that are certified by the American Petroleum Institute (API) are widely recognized in the oil and gas industry for their exceptional quality and reliability. These certifications not only help in ensuring that the valves meet legal requirements but also enhance their credibility in various industrial applications. Focusing on these essential standards and certifications will lead to informed purchasing decisions, resulting in better operational efficiency and long-term performance.

When it comes to selecting the best ball valve for industrial applications, understanding comparative performance metrics is crucial. Recent industry reports indicate that ball valves exhibit a lower flow resistance compared to gate valves, with a typical pressure drop of approximately 5% at standard operating conditions. This minimal pressure drop not only enhances efficiency but also conserves energy, making ball valves a preferred choice in many piping systems.

In evaluating the top-rated ball valves on the market, factors such as durability, material quality, and operational pressure ratings stand out. For instance, the latest reviews suggest that valves made from forged stainless steel offer superior longevity and resistance to corrosion, a vital aspect in chemical processing environments. Additionally, valves boasting a full port design can deliver better flow rates, outperforming conventional port designs by up to 30%.

**Tips:** Always check the valve's leak rate performance as it directly impacts system reliability; values below 0.1% are generally recommended for critical applications. Moreover, consider the operating temperature and pressure limits specified by the manufacturer to ensure compatibility with your system's requirements. Investing time in understanding these metrics can lead to significant cost savings and improved operational efficiency in the long run.