The ball check valve is an essential component in numerous fluid systems, offering reliable performance and efficiency in preventing backflow. According to industry reports, the global valve market is projected to reach a value of approximately $100 billion by 2025, with check valves, including ball check valves, playing a significant role due to their increasing applications across various sectors such as water and wastewater treatment, oil and gas, and HVAC systems.

One of the key advantages of using a ball check valve is its simple yet effective design, which allows for quick installation and maintenance, contributing to lower operational costs. In a recent analysis, it was found that proper valve selection can reduce energy consumption by up to 20% in fluid handling processes. This efficiency is particularly crucial in industrial settings where minimizing downtime and maximizing performance is vital to business success.

Furthermore, with the rise in automation and smart technologies, the demand for robust and reliable components like ball check valves is on the rise. Their durability and ability to withstand varying pressure and temperature conditions further position them as a preferred choice in many fluid control applications. As industries continue to evolve, understanding the benefits of ball check valves will be paramount for optimizing system performance and ensuring sustainability.

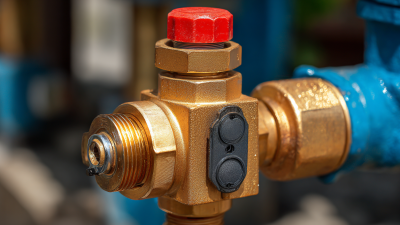

Ball check valves are essential components in fluid systems, designed to prevent backflow and ensure efficient flow management. These valves operate using a spherical ball that moves within a seat, allowing fluid to flow in one direction while sealing off the reverse flow. This simple yet effective mechanism is what makes ball check valves a favored choice in various industries, including water treatment, oil and gas, and food processing. According to a report by the International Journal of Engineering Technology, the demand for check valves, particularly ball check types, is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2022 to 2028, emphasizing their critical role in industrial applications.

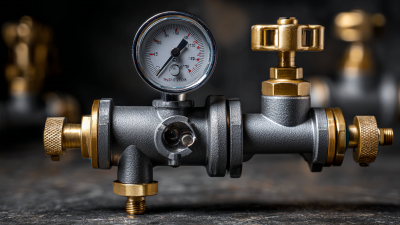

When selecting a ball check valve, it's essential to consider material compatibility and pressure ratings. For example, valves made from stainless steel are ideal for environments involving corrosive substances, while plastic options may suffice for less demanding applications. It's recommended to consult fluid dynamics charts to accurately gauge flow rates and backpressure scenarios to ensure proper installation and function.

Tip: Regular maintenance of ball check valves can significantly extend their lifespan. Inspect the valves periodically for signs of wear and tear, and replace them if you notice any leaks or performance issues. This proactive approach can help minimize downtime and enhance operational efficiency.

Ball check valves are vital components in fluid systems, offering numerous advantages that enhance efficiency and reliability. One of the primary benefits of using ball check valves is their ability to prevent backflow, ensuring that fluids flow in the desired direction. This feature is particularly beneficial in applications where maintaining the integrity of the system is crucial, such as in water supply lines, sewage systems, and various industrial processes. Their design allows them to operate effectively with minimal pressure drop, making them an efficient choice in many fluid transfer applications.

Another key advantage of ball check valves is their versatility. They can handle a wide range of fluids, including corrosive and viscous materials, which makes them suitable for different sectors such as agriculture, pharmaceuticals, and manufacturing. Their simple yet robust construction ensures consistent performance with minimal maintenance. When installed correctly, ball check valves can significantly reduce the risk of system failures and leaks, thereby providing peace of mind in critical operations.

Tips: When selecting a ball check valve for your system, consider factors such as the fluid type, temperature, and pressure to ensure optimal compatibility and performance. Additionally, regular inspections can help identify any wear or malfunctions early, minimizing unexpected downtime.

Ball check valves are widely utilized across varied industries due to their effective backflow prevention capabilities. In the water and wastewater management sector, these valves ensure that water flows in one direction, preventing contamination and ensuring reliability in municipal water supply systems. Their design minimizes pressure drop and enhances flow efficiency, making them ideal for pumping stations and sewage treatment plants.

In the oil and gas industry, ball check valves play a critical role in safeguarding pipelines and storage facilities. They are employed in crude oil transportation and refining processes to prevent backflow, which could lead to hazardous situations. Additionally, in the chemical processing sector, these valves are essential for maintaining material integrity and preventing spills. Their ability to withstand harsh chemicals and extreme temperatures highlights their versatility and reliability, making them indispensable in many industrial applications.

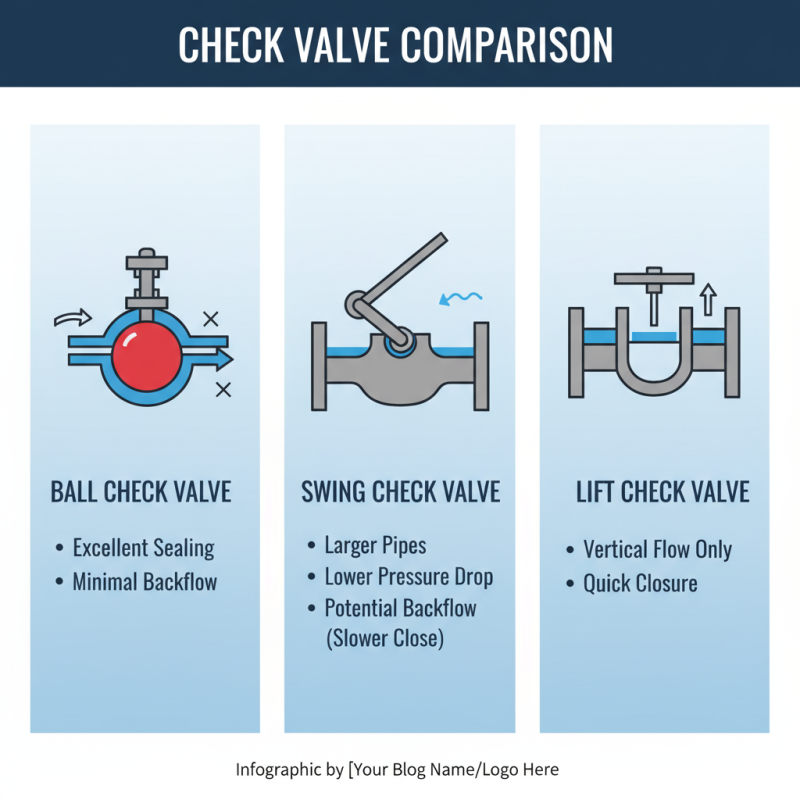

When evaluating check valves, it's essential to compare the ball check valve with other types such as swing and lift check valves. Each has its unique characteristics and suitability for various applications. Ball check valves utilize a smooth, spherical ball that provides excellent sealing capabilities, making them ideal for applications requiring minimal backflow. In contrast, swing check valves operate using a hinged disc that swings open and closed, which can introduce potential turbulence in the flow. While swing check valves are often favored for larger pipe systems due to their lower pressure drop, they may not close as quickly as ball check valves, leading to potential backflow in certain situations.

Lift check valves are another alternative that operates by lifting a disc from its seat when fluid flows in one direction. This design allows for higher flow rates, but it can suffer from chatter and is more susceptible to wear over time. In contrast, ball check valves are appreciated for their durability and low maintenance needs, characteristics that make them advantageous in applications dealing with slurries or viscous fluids. Each type of check valve has its pros and cons, depending on factors like flow characteristics, pressure requirements, and maintenance convenience, emphasizing the importance of choosing the right valve for the specific application at hand.

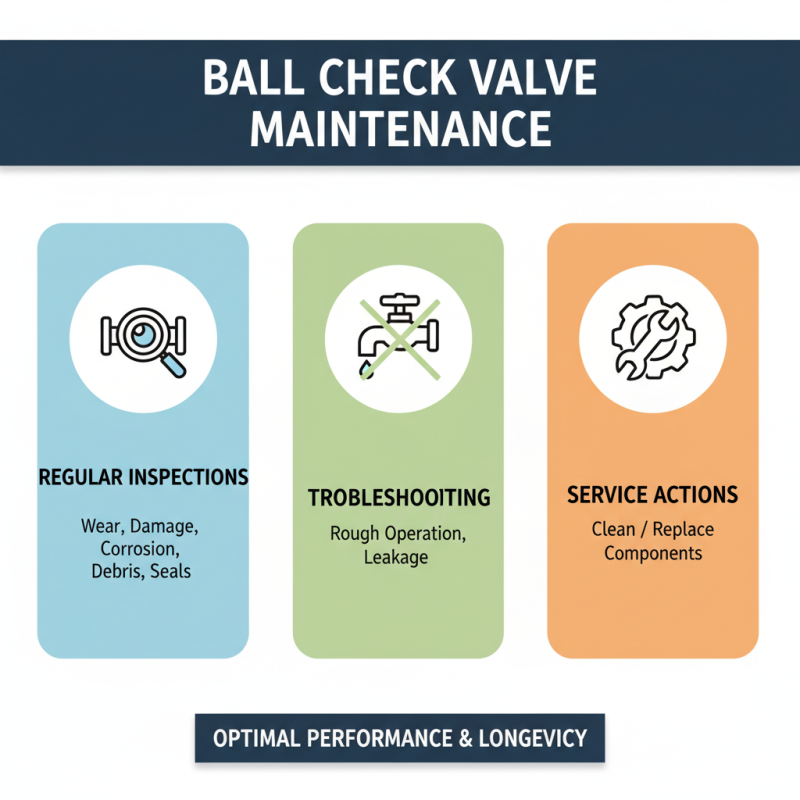

Proper maintenance of ball check valves is essential to ensure their optimal performance and longevity. Regular inspections should be conducted to identify any signs of wear or damage. Look for signs of corrosion, debris build-up, or seal deterioration, as these can significantly affect the valve's functionality. If the valve is not operating smoothly or is showing signs of leaking, it may be necessary to clean or replace components to restore full operation.

Additionally, using the appropriate lubricants can enhance the valve's performance. Lubricants should be compatible with the materials of the valve to prevent degradation. The environment in which the valve operates also plays a critical role in its maintenance; extreme temperatures or high-pressure conditions can accelerate wear. Implementing a routine maintenance schedule that includes checking for leaks and functionality tests can prevent unexpected failures and costly downtime in systems reliant on ball check valves.