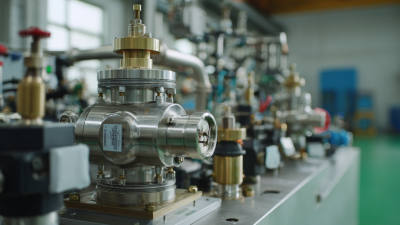

In modern fluid systems, the role of the one way valve cannot be overstated, as it ensures the unidirectional flow of liquids and gases, thereby enhancing system efficiency and safety. According to a report by the Global Valves Market, the one way valve segment is anticipated to grow significantly, driven by the increasing demand for advanced fluid control technologies across industries such as oil and gas, water management, and pharmaceuticals. The report highlights that effective use of one way valves can reduce the risk of backflow, which is a major concern in fluid transport systems, potentially leading to contamination and system failure. As industries continue to evolve and adopt more complex fluid dynamics, understanding the integral function of one way valves becomes crucial for engineers and system designers aiming to optimize performance while minimizing risks associated with fluid systems.

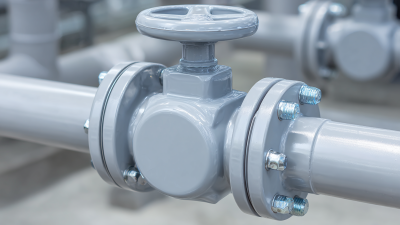

One way valves, also known as check valves, play a crucial role in fluid dynamics by allowing fluid to flow in a single direction while preventing backflow. This functionality is essential in various applications, from water supply systems to hydraulic machinery. When fluid enters the valve, it pushes a disc or ball to open the path, but if reverse pressure occurs, the mechanism closes tightly, ensuring the system remains efficient and safe. This simple yet effective design helps maintain pressure, reduces the risk of contamination, and protects equipment from potential damage caused by backflows.

**Tips:** When selecting a one way valve for your fluid system, consider the flow rate and pressure conditions. Ensure that the valve material is compatible with the fluid being transported to prevent corrosion or degradation. Proper installation is also vital; make sure to follow the manufacturer’s guidelines to ensure optimal performance and longevity.

In addition to their primary function, one way valves can enhance energy efficiency within a system. By controlling the direction of fluid flow, these valves minimize energy loss that could occur from re-circulation. They are especially beneficial in systems where fluid needs to be directed to specific areas without allowing it to return. It’s important to conduct regular maintenance checks on these valves to ensure they are operating as intended, as any malfunctions could lead to significant operational issues.

This chart illustrates the efficiency of one way valves in various fluid systems, showing the flow rate (in liters per minute) across different applications. The data reflects the typical performance of one way valves used in industrial, residential, and commercial systems.

One way valves play a crucial role in modern fluid systems, offering several key benefits that enhance the efficiency and safety of operations. According to a report by the International Journal of Fluid Mechanics, the implementation of one way valves can reduce fluid backflow by over 80%, thus protecting pumps and other components from potential damage caused by reverse flow. This not only prolongs the lifespan of equipment but also minimizes maintenance costs, leading to significant savings for businesses.

In addition to safeguarding equipment, one way valves improve system efficiency by maintaining optimal pressure levels. Research from the American Society of Mechanical Engineers has shown that systems utilizing one way valves can achieve a 15% increase in energy efficiency, as these valves prevent energy loss that occurs when fluid flows in unintended directions. This results in smoother operation and reduced energy consumption, which is essential in today’s environmentally conscious landscape.

Tips: When selecting one way valves for your fluid system, consider materials that are resistant to corrosion and wear, especially in harsh environments. Regularly inspect and maintain these valves to ensure optimal performance and longevity. Furthermore, always refer to industry standards and guidelines to select the right size and type of valve for your specific application.

| Key Benefits | Description | Application Examples |

|---|---|---|

| Prevent Backflow | One way valves ensure that fluid flows in only one direction, preventing reverse flow that could damage pumps and other system components. | Water supply systems, wastewater treatment plants. |

| Improved Efficiency | By allowing fluid to flow smoothly without obstruction, one way valves enhance overall system efficiency. | Hydraulic systems, irrigation systems. |

| Reduced Maintenance | Fewer components to check and repair, leading to lower maintenance costs and downtime. | Industrial piping networks, HVAC systems. |

| Cost-Effectiveness | One way valves provide a simple and effective solution that reduces costs over time. | Commercial plumbing, fuel transportation. |

| Versatility | Can be used in various applications and with different types of fluids. | Chemical processing, food and beverage industry. |

One way valves, also known as check valves, play a crucial role in modern fluid systems by allowing fluid to flow in one direction while preventing backflow. Their importance is evident across various industries, with common applications ranging from water and wastewater management to oil and gas production. According to a report by Grand View Research, the global check valve market size was valued at approximately USD 4.02 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of 4.6% from 2021 to 2028, highlighting their essential role in maintaining efficient fluid transfer.

In the food and beverage industry, one way valves are utilized to ensure sanitary conditions during production and packaging processes. They prevent contamination by stopping backflow from existing fluid lines, ensuring that the quality of the product remains uncompromised. Additionally, in the pharmaceutical sector, these valves are critical for the accurate dispensing of medications, as they maintain the integrity of the flow path and minimize the potential for cross-contamination.

**Tips:** When selecting one way valves for your system, consider factors such as pressure ratings, material compatibility, and the specific application requirements. Regular maintenance is also essential to ensure optimal performance and longevity.

One way valves play a crucial role in modern fluid systems by allowing fluid to flow in a single direction while preventing backflow. To ensure optimal performance and longevity of these valves, regular maintenance is essential. It is important to inspect the valves periodically for signs of wear or damage, as even minor issues can lead to significant disruptions in fluid flow and system efficiency.

Another key aspect of maintenance is to keep the valve clean and free from debris. Accumulation of dirt or other contaminants can impair the functioning of the valve, leading to operational failures. Utilizing proper cleaning techniques, such as flushing the valve with appropriate solvents, can greatly reduce the risk of clogging. Additionally, monitoring the pressure levels within the system can help detect any irregularities, which may indicate that the valve is not functioning correctly and requires immediate attention. By implementing these maintenance tips, operators can ensure that one way valves continue to perform reliably within fluid systems.

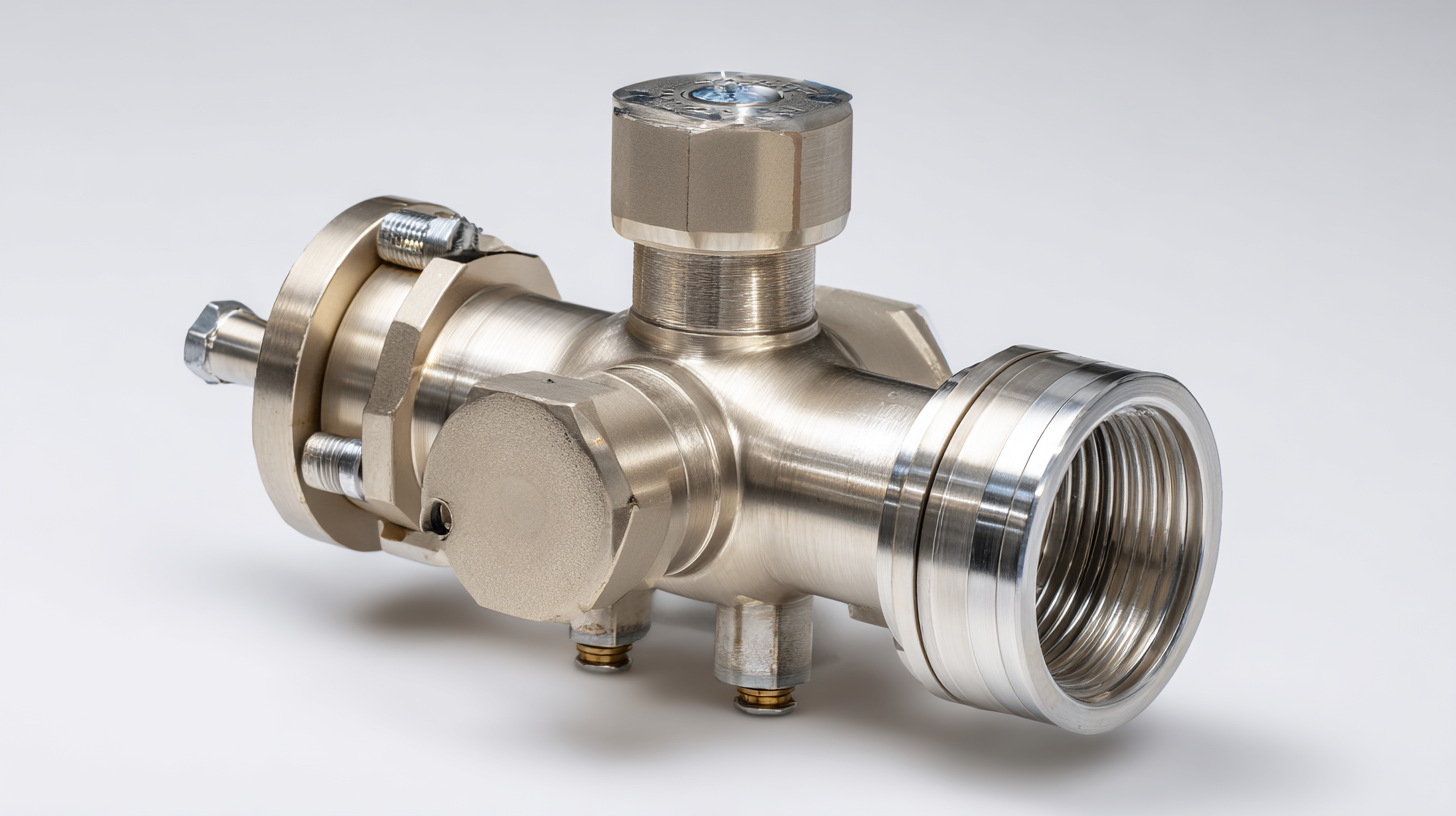

When selecting a one-way valve for fluid management systems, it's crucial to consider various factors to ensure optimal performance. According to industry reports, the right one-way valve can significantly contribute to efficiency and reliability in a fluid system. Factors such as fluid type, pressure levels, and flow rates must be taken into account. For instance, a study highlighted that using the appropriate valve type can improve flow control by up to 20%, which is essential in applications ranging from water filtration to industrial processes.

Additionally, the material of the valve plays a vital role in its effectiveness. Data shows that corrosion-resistant materials can extend the lifespan of one-way valves by as much as 30%. This is particularly important in environments where chemical exposure is a concern. As fluid management needs evolve, the demand for specialized one-way valves continues to rise, making it essential for engineers and stakeholders to stay informed about the latest technologies and materials in the market to choose the best options for their specific applications.