In the realm of modern industry applications, the importance of ball valves cannot be overstated. As a critical component in fluid control systems, these valves ensure efficient operation and safety across a plethora of environments, from manufacturing to chemical processing. Industry expert John Smith, a respected engineer with over 20 years of experience in valve technology, emphasizes, "The reliability of a ball valve can significantly impact the performance and security of an entire system." His insight underscores the pivotal role these valves play in maintaining operational integrity.

Ball valves are not just simple mechanical devices; they represent a sophisticated solution to the challenges posed by diverse fluid management needs. With their ability to provide a tight seal and quick operation, they have become integral to industries such as oil and gas, water treatment, and food processing. The ongoing advancement in design and materials further enhances their functionality, making ball valves a preferred choice among engineers and technicians alike. As we dive deeper into the nuances of ball valves, it is essential to appreciate their multifaceted role and how they contribute to the seamless operation of modern industrial systems.

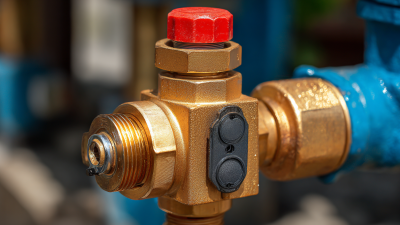

Ball valves have become indispensable components in flow control systems across various industries. Their design, featuring a spherical disc that rotates to open or close the flow, allows for quick shut-off and excellent flow regulation. This functionality makes them suitable for applications ranging from oil and gas to chemical processing and water treatment. The ability to provide tight sealing and minimal flow resistance enhances operational efficiency, allowing industries to maintain precise control over their systems.

When implementing ball valves in your operations, consider the following tips: first, ensure that you select the appropriate size and pressure rating for your specific application to avoid leaks or failures. Secondly, regular maintenance is essential; inspect the valve seats and seals periodically to ensure optimal performance and longevity. Lastly, keep in mind that the material of the ball valve should be compatible with the fluids it will handle to prevent corrosion and damage.

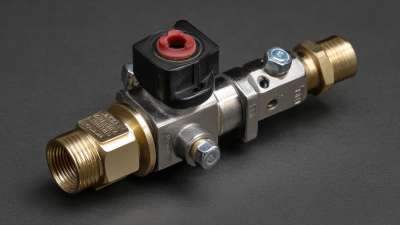

The versatility of ball valves also extends to their ease of automation. Many industries have adopted automated ball valves, which can be integrated with modern control systems for enhanced monitoring and operation. This integration allows for more precise flow control and the ability to quickly respond to changes in process conditions, making ball valves a vital component in modern industrial setups.

Ball valves play a crucial role in modern industrial applications due to their unique design and functionality. One of the key advantages of using ball valves is their ability to provide a tight seal, which minimizes the risk of leaks. This is particularly important in sectors such as oil and gas, water treatment, and chemicals, where the containment of fluids is essential for safety and environmental protection. The spherical shape of the ball enables quick and efficient shutoff, allowing for excellent control over fluid flow.

Another significant benefit of ball valves is their simplicity and durability. They are designed for easy operation, often requiring just a quarter turn to either fully open or close the valve, which adds to their efficiency in high-volume applications. Additionally, ball valves are constructed from robust materials that can withstand high pressures and extreme temperatures, making them suitable for a wide range of industrial environments. Their low maintenance requirements further enhance their appeal, ensuring that they continue to function effectively for long periods with minimal intervention.

In modern industrial applications, choosing the right valve can significantly influence system efficiency and reliability. Ball valves stand out due to their superior flow control capabilities compared to other valve types. According to a report by MarketsandMarkets, the global ball valve market is projected to reach USD 8.68 billion by 2025, growing at a CAGR of 6.3% from 2020. This growth is largely attributed to the increasing demand for reliable and high-performance flow control solutions across various sectors, including oil and gas, power generation, and water treatment.

In modern industrial applications, choosing the right valve can significantly influence system efficiency and reliability. Ball valves stand out due to their superior flow control capabilities compared to other valve types. According to a report by MarketsandMarkets, the global ball valve market is projected to reach USD 8.68 billion by 2025, growing at a CAGR of 6.3% from 2020. This growth is largely attributed to the increasing demand for reliable and high-performance flow control solutions across various sectors, including oil and gas, power generation, and water treatment.

When comparing ball valves with gate valves and globe valves, one key advantage is their quick opening and closing mechanism, which can be completed with just a quarter turn. This not only enhances operational efficiency but also minimizes the risk of leaks. A survey conducted by the Valve Manufacturers Association indicated that over 55% of industrial professionals prefer ball valves for their low torque requirements and durability under high pressure and temperature conditions. As industries continue to evolve, the versatility and reliability of ball valves make them an essential choice for optimizing performance and safety in complex fluid handling systems.

When selecting the right ball valve for industrial applications, several critical factors must be considered to ensure optimal performance and reliability. One of the primary considerations is the size and type of valve required for the specific system. Similar to how one must carefully size turbo systems for maximum horsepower, the appropriate ball valve must match the system’s requirements to manage flow rates and pressure effectively. Additionally, the material composition of the valve plays a crucial role in its durability and compatibility with the fluids being transported.

Cost efficiency is another vital factor in the selection process. While it may be tempting to opt for the cheapest option, it’s important to evaluate long-term operational costs, maintenance needs, and potential downtime caused by valve failures. Understanding how the environment—such as temperature and pressure ranges—affects valve performance can also guide the choice. Hence, evaluating all these dimensions ensures that the selected ball valve not only meets immediate specifications but also contributes to the overall efficiency and sustainability of the operation.

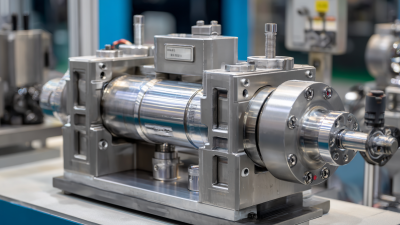

Ball valves have become a critical component in modern industrial applications due to their reliability and efficiency. Recent innovations in ball valve technology have led to significant improvements in performance, safety, and operational efficiency. For instance, advanced materials and manufacturing techniques have resulted in valves that can withstand higher pressures and temperatures, making them suitable for a wide range of applications from oil and gas to chemical processing.

Ball valves have become a critical component in modern industrial applications due to their reliability and efficiency. Recent innovations in ball valve technology have led to significant improvements in performance, safety, and operational efficiency. For instance, advanced materials and manufacturing techniques have resulted in valves that can withstand higher pressures and temperatures, making them suitable for a wide range of applications from oil and gas to chemical processing.

To maximize the benefits of these technological advancements, industries can adopt a few best practices. Tip: Always ensure the chosen ball valve materials are compatible with the fluids being handled to prevent corrosion and extend the lifespan of the valve. Additionally, regular maintenance routines can help identify potential issues before they escalate, ensuring seamless operations.

Another area of innovation is the integration of smart technology with ball valves. This allows for real-time monitoring and remote control, enabling companies to optimize their processes and respond swiftly to any operational changes. Tip: Investing in smart valve actuators can enhance operational oversight and reduce downtime, leading to better resource management in industrial settings.