Choosing the right electric ball valve can significantly impact the efficiency and reliability of your fluid control systems. As with any equipment, understanding your specific needs and the operational context is crucial. Industry expert, Dr. Emily Carter, a renowned engineer specializing in fluid dynamics, emphasizes the importance of this selection process: "The right electric ball valve can enhance performance while ensuring safety and energy savings."

In today's market, there are myriad options available, ranging from size and material to varying control mechanisms and power sources. With advancements in technology, electric ball valves have evolved to provide enhanced precision and responsiveness, making them an excellent choice for a variety of applications, from HVAC systems to industrial processes.

Navigating through these choices can be overwhelming, but by focusing on key factors such as application requirements, compatibility with existing systems, and operational efficiency, you can make an informed decision. Ensuring that your selected electric ball valve aligns with your specific needs will not only optimize your operations but also contribute to long-term reliability and maintenance savings.

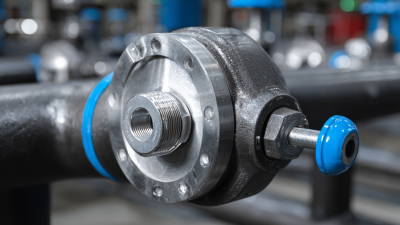

When selecting the best electric ball valve for your needs, the size of the valve is a critical factor that cannot be overlooked. The correct valve size ensures optimal flow rates, minimizes pressure drop, and guarantees efficient system performance. One key consideration in determining the appropriate size is the diameter of the piping system. It is essential to match the ball valve's size with the existing pipes to maintain consistent flow and prevent potential bottlenecks that could impair operations.

Another important aspect to consider is the application requirements, which include flow rate, pressure drop, and the nature of the fluid being controlled. Different applications may demand varying sizes for effective control. For instance, a larger valve may be necessary for high-flow applications, while smaller sizes could suffice for precise flow control in low-volume systems. Additionally, the pressure rating of the valve and the specific operating conditions should align with the chosen size to ensure reliability and longevity in service. By carefully evaluating these factors, you can select an electric ball valve that meets your specific needs while optimizing performance.

This chart illustrates the flow capacity (in gallons per minute) of various electric ball valve sizes. When choosing the right electric ball valve, consider the flow capacity required for your application to ensure optimal performance.

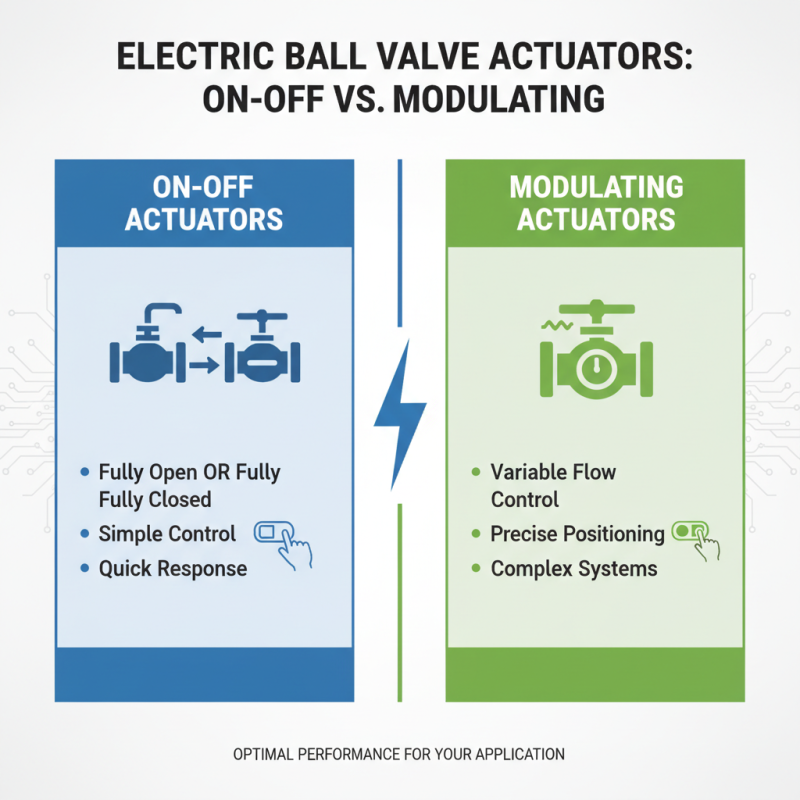

When selecting an electric ball valve, understanding the various types of electric actuators is crucial for ensuring optimal performance in your specific application. Electric actuators can generally be categorized into two main types: on-off and modulating actuators. On-off actuators are designed for applications where the valve either needs to be fully open or fully closed. They are ideal for systems that require a simple control mechanism, providing quick response times and straightforward installation.

On the other hand, modulating actuators offer variable control, allowing for precise flow regulation. These actuators are typically used in more complex systems requiring gradual adjustment of flow rates. Modulating actuators can be more intricate in their design and operation, accommodating various input signals and providing feedback to ensure stable control. Understanding these distinctions will help you select an actuator that best meets your operational needs, whether you prioritize swift on-off functionality or nuanced flow control.

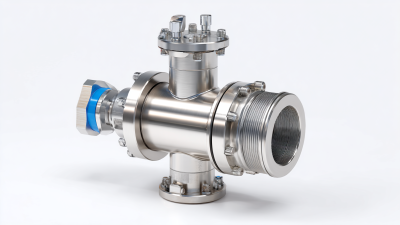

When selecting an electric ball valve, material compatibility is a crucial factor that directly impacts the valve's longevity and safety. The materials used in both the valve and the associated piping should be compatible with the fluids they will handle.  For instance, corrosive liquids or gases may require valves made from specialized materials like stainless steel or certain polymers that resist chemical degradation. An assessment of the operating environment, including temperature and pressure conditions, is essential to ensure that the materials chosen can withstand these factors without compromising performance.

For instance, corrosive liquids or gases may require valves made from specialized materials like stainless steel or certain polymers that resist chemical degradation. An assessment of the operating environment, including temperature and pressure conditions, is essential to ensure that the materials chosen can withstand these factors without compromising performance.

Furthermore, it's important to consider how the valve's material interacts with the media. For example, if a valve is constructed from a material that reacts adversely with the fluid, it could lead to premature failure, leaks, or even hazardous situations. Conducting a thorough compatibility evaluation can help inform choices around sealing materials, coatings, and construction types.

By prioritizing material compatibility, users can enhance not only the operational efficiency of the electric ball valve but also ensure a safer environment in their applications.

When selecting the best electric ball valve for your application, understanding key performance metrics like torque, pressure ratings, and response times is essential. Torque is a critical factor, as it determines how effectively the valve can open and close against the pressure of the fluid within the system. A valve with insufficient torque may struggle to operate, leading to inefficient flow control or even valve failure in higher-pressure environments. Therefore, it's vital to assess the torque requirements based on the specific conditions of your application.

Pressure ratings are another crucial metric to consider. They indicate the maximum pressure that the valve can handle without compromising its integrity. Choosing a valve with an appropriate pressure rating ensures that it can operate safely and efficiently under the expected conditions of your fluid system. Additionally, it helps to prevent issues like leaks or catastrophic failures that can arise from exceeding the valve's rated pressure.

Response times also play a significant role in the overall performance of electric ball valves. A quick response time is essential in applications where timely flow adjustments are necessary to maintain system stability or safety. Valves with rapid actuation capabilities can provide better control over the flow, enhancing the responsiveness of the entire system. When evaluating electric ball valves, prioritize these performance metrics to find a valve that meets the precise demands of your operation.

When selecting the best electric ball valve for your needs, balancing cost and quality is crucial. High-quality electric ball valves often come with a higher price tag, but they can provide better performance, durability, and efficiency in the long run. Investing in a quality valve can reduce maintenance costs and prevent unexpected failures, which might lead to costly repairs and downtime. It’s essential to assess the requirements of your application and determine how the valve's construction and materials will influence its longevity and performance.

**Tips: Evaluate different suppliers and their offerings to ensure you're not compromising on quality for a lower price. Look for customer reviews and feedback to get insights into the reliability and performance of the valves you’re considering. Additionally, consider the warranty and after-sales support, as these factors can significantly impact the overall value of your investment.**

Another important aspect to consider is the specific features required for your application. Some valves are designed for high-pressure or high-temperature environments, while others may be more suited to regular operational use. Understanding your unique needs will guide you in selecting a valve that meets both your performance criteria and budget.

**Tips: Create a checklist of the features and specifications that are critical for your application, such as size, pressure rating, and actuation method. This will help streamline your decision-making process and ensure you invest in a valve that is well-suited to your operational requirements.**

| Valve Size (inches) | Material | Connection Type | Operating Voltage (V) | Control Type | Cost (USD) | Quality Rating (1-5) |

|---|---|---|---|---|---|---|

| 1 | Brass | Threaded | 24 | On/Off | 150 | 4 |

| 2 | Stainless Steel | Flanged | 110 | Modulating | 300 | 5 |

| 3 | PVC | Socket | 24 | On/Off | 75 | 3 |

| 4 | Bronze | Threaded | 220 | Modulating | 220 | 4 |

| 5 | Cast Iron | Flanged | 380 | On/Off | 500 | 5 |