In the world of fluid control, the pressure regulator valve stands as a crucial component that ensures the safe and efficient operation of various systems. Whether in industrial applications, HVAC systems, or chemical processing, selecting the right pressure regulator valve is essential to maintaining optimal pressure and flow rates. However, the decision-making process can often be complicated by industry production standards and the various problems associated with different valve types. This ultimate guide aims to demystify the selection process of pressure regulator valves by highlighting the key considerations, potential challenges, and the best practices to follow. By understanding these factors, you can make an informed choice that aligns with your specific needs, ultimately leading to improved performance and reliability in your applications.

When selecting a pressure regulator valve for your application, understanding the different types available is crucial. Pressure regulators are categorized into two main types: single-stage and multi-stage. Single-stage regulators provide rapid adjustments and are typically used in applications where pressure changes infrequently. According to a report from the International Society of Automation, these are ideal for industries like beverage carbonation, where maintaining consistent pressure is key. In contrast, multi-stage regulators are more suited for processes requiring precise and stable pressure control over a wide range of flow rates, commonly found in chemical processing.

Tips: When choosing between single-stage and multi-stage regulators, consider the pressure fluctuations typical in your application. If your system experiences frequent pressure changes, opt for a single-stage regulator for quicker response times.

Additionally, it's essential to evaluate the materials used in the regulator. A study published by the American Institute of Chemical Engineers highlights that materials like stainless steel provide better corrosion resistance, making them suitable for harsh environments. Ensure that the valve can withstand the specific operational conditions relevant to your setup, especially if dealing with gases or corrosive substances.

Tips: Always check the manufacturer's specifications for material compatibility with your application to prevent premature failure and costly downtime.

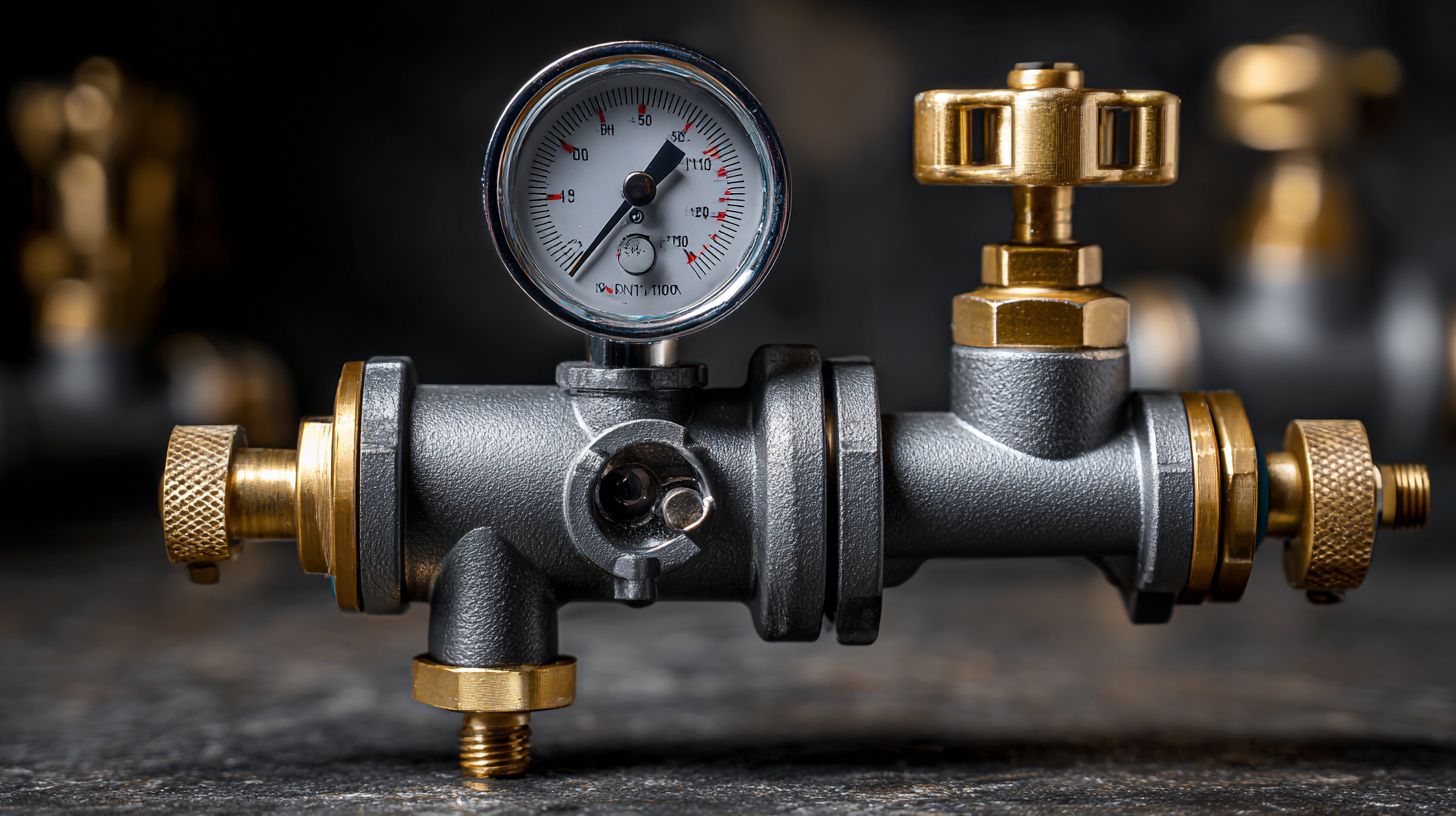

When it comes to selecting the best pressure regulator valve for your specific needs, understanding the key factors that influence their performance is crucial. One of the primary aspects to consider is the material used in the valve construction. Different materials can withstand varying pressure levels and environmental conditions. For example, brass and stainless steel are known for their durability and resistance to corrosion, making them ideal for industrial applications, while plastic valves may be more suitable for lower-pressure systems.

Another vital factor is the flow rate, which determines how much fluid the valve can handle at any given time. Choosing a valve with the appropriate flow rate ensures that your system operates efficiently without unnecessary bottlenecks. Additionally, valve sensitivity plays a significant role in maintaining desired pressure levels. High-sensitivity regulators can quickly respond to fluctuations, ensuring a stable pressure output that is essential for many processes. By analyzing these data-driven insights, you can make informed decisions that enhance the effectiveness of your pressure regulation systems.

When selecting a pressure regulator valve, understanding the significance of flow rate and pressure drop is crucial. Flow rate, measured in liters per minute or gallons per minute, reflects how much fluid can pass through the valve at a given time. A pressure regulator valve that cannot handle the required flow rate may lead to system inefficiencies, affecting everything from performance to safety. Calculating the flow rate needed for your specific application allows you to narrow down your choices, ensuring that the valve meets operational demands without compromising performance.

Equally important is the pressure drop, which refers to the difference in pressure between the inlet and outlet of the valve. A significant pressure drop can indicate a restriction in flow, leading to decreased efficiency and possible system failures. It's essential to select a valve that maintains an acceptable pressure drop level while providing consistent flow. By analyzing both flow rate and pressure drop, you can make informed decisions to select a pressure regulator valve that optimizes your system's functionality and enhances overall performance.

When selecting a pressure regulator valve, the

material of construction plays a pivotal role in determining both durability and cost. Common materials used in these valves include brass, stainless steel, and plastic.

Brass valves are often favored for their

excellent durability and resistance to corrosion, making them suitable for a range of applications.

However, costs can escalate depending on the alloy used and the complexity of the valve design.

Stainless steel valves, while generally more expensive, offer

superior strength and resistance to high pressures and extreme temperatures. This makes them ideal for

industrial settings where reliability is paramount. On the other hand,

plastic pressure regulators are lightweight and cost-effective, but their

suitability is limited to less demanding environments, as they may not withstand high pressures or aggressive fluids.

Understanding the trade-offs between these materials is crucial for making an informed decision that balances longevity and

budget constraints.

Maintaining the efficiency and longevity of your pressure regulator valve is crucial for ensuring optimal performance in various applications, from industrial operations to residential systems. According to a report by the International Society of Automation (ISA), regular maintenance can improve the life expectancy of a pressure regulator valve by up to 50%. This statistic highlights the importance of proactive care and scheduled inspections, which can prevent unexpected failures and costly downtime.

One effective tip is to establish a routine maintenance schedule that includes checking for leaks, corrosion, and cleanliness. Regularly inspect the valve for any signs of wear, as even minor issues can lead to significant inefficiencies. Additionally, consider using high-quality filters to prevent debris from entering the valve, as studies show that 70% of pressure-related failures are linked to contamination.

Another essential aspect of maintaining pressure regulator valves is the calibration process. Ensuring that the regulator is calibrated correctly not only enhances efficiency but also contributes to safety. Misadjusted regulators can lead to pressure surges, which might cause system failures. Keeping track of calibration intervals and adhering to manufacturer guidelines can further enhance your valve’s lifespan and functionality.