When it comes to fluid control systems, selecting the right check valve is crucial for ensuring optimal performance and reliability. Check valves play a vital role in preventing backflow, protecting pumping equipment, and maintaining system efficiency. With a plethora of options available in the market, making an informed choice can be daunting. This guide aims to simplify the process by providing 10 essential tips tailored to meet your specific needs.

Understanding the various types of check valves, their material compositions, and appropriate applications is imperative for successful implementation. Whether you are working in a residential, commercial, or industrial setting, choosing the correct check valve can significantly impact the longevity and effectiveness of your system. From assessing pressure ratings to considering the flow direction, each factor is essential to ensure that your check valve operates flawlessly within your system. Join us as we delve into these critical considerations that will empower you to make the best decision for your fluid management needs in 2025 and beyond.

When selecting the right check valve for your specific application, understanding the different types available is crucial. Check valves, designed to prevent backflow, come in various forms such as swing, globe, and ball check valves. Each type has unique advantages tailored to specific operational conditions. For instance, swing check valves are ideal for high-flow applications due to their low-pressure drop, while ball check valves provide a more compact solution suited for tight spaces and high-pressure systems.

Tip 1: Evaluate the fluid characteristics—knowing whether you're dealing with corrosive, viscous, or non-viscous fluids can significantly influence your choice. According to a report by the American Society of Mechanical Engineers, 37% of valve failures are due to selecting the wrong valve type for the fluid being handled.

Tip 2: Consider the installation position—vertical or horizontal installation can affect the performance of different check valve types. Data from a recent industry analysis shows that improper installation can reduce efficient functioning by up to 20%.

By understanding these factors and incorporating professional recommendations, you can ensure the longevity and reliability of your check valve in operational settings.

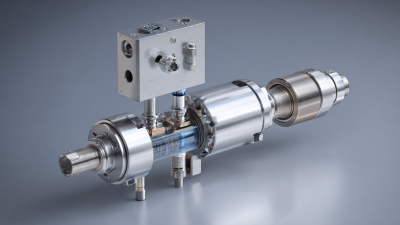

When selecting a check valve, understanding the sizing factors is critical for ensuring optimal performance. One key consideration is the flow rate of the fluid passing through the valve. According to a report by the American Society of Mechanical Engineers (ASME), mismatched flow rates can lead to pressure drops and reduced efficiency, highlighting the importance of consulting manufacturers' specifications to determine the appropriate valve size for specific applications.

Another vital aspect is the type of fluid being handled. Different fluids can have unique properties such as viscosity, density, and temperature that influence the valve's performance. The Hydraulic Institute emphasizes that choosing a valve designed for the specific characteristics of the fluid can significantly enhance reliability and longevity. For instance, corrosive fluids require materials that resist degradation, while high-viscosity fluids may necessitate larger or specially designed valves to maintain efficient flow and prevent backflow issues.

Understanding these factors will steer users toward more effective check valve solutions tailored to their operational needs.

When selecting a check valve for corrosive environments, material selection is crucial. The right material can enhance the longevity and effectiveness of the valve, ensuring it withstands the harsh conditions it may face. Common materials for corrosive applications include stainless steel, PVC, and various alloys designed to resist specific chemicals. Before making a choice, it's essential to assess the type of fluid, its temperature, and concentration levels.

One helpful tip is to consult the manufacturer's material compatibility charts, which can provide insights into which materials will perform best with the fluids you're handling. Additionally, consider the valve type—swing, lift, or diaphragm—and how it will interact with your system. Selecting a valve that minimizes turbulence and pressure drops is vital, as this can affect performance and longevity.

Another important aspect to keep in mind is the environmental conditions surrounding the valve. Exposure to extreme temperatures, humidity, or abrasive materials can influence which material is best suited for your application. By evaluating these factors carefully, you can make an informed decision that will protect your system and enhance its efficiency.

When selecting a check valve, one of the most critical aspects to consider is the pressure rating. Pressure ratings indicate the maximum pressure that a valve can handle without compromising its structural integrity. Choosing a valve with a suitable pressure rating ensures that it can withstand the operational conditions of your system, preventing potential failures that could lead to costly downtime or safety hazards. Understanding the specific pressure requirements of your application will help in making an informed choice, whether it involves high-pressure fluid transfer or standard industrial applications.

Moreover, the pressure rating directly impacts the functionality of the check valve. A valve rated for insufficient pressure may not fully seal during backflow conditions, allowing unwanted reverse flow that could damage equipment downstream. Conversely, a valve with an excessively high-pressure rating may be unnecessarily costly and bulky for low-pressure applications. Therefore, balancing the specific needs of your system with the appropriate pressure rating is essential for optimizing performance. Careful evaluation of these aspects ensures effective prevention of backflow, contributing to the overall reliability and efficiency of your fluid handling processes.

When selecting a check valve, understanding flow direction is paramount. Check valves are designed to allow flow in one direction while preventing backflow, which makes the inherent flow direction critical in a system. Incorrect installation, where the valve is oriented to permit reverse flow, can lead to catastrophic system failures, causing damage to equipment and increased maintenance costs. Therefore, it is essential to ensure that the valve is installed correctly, adhering to the manufacturer’s specifications regarding flow direction.

Installation orientation also plays a significant role in the performance and longevity of a check valve. The position—horizontal or vertical—can impact how fluid dynamics interact within the valve. For instance, vertical installations may require specific types of check valves to maintain efficiency and reduce turbulence. Moreover, the choice of valve type, whether swing, lift, or ball, can affect how flow velocity influences the operational stability of the valve in various orientations. Thus, assessing both flow direction and installation orientation carefully is critical to ensuring optimal performance of check valves in any system.