In the realm of modern automation, the deployment of water solenoid valves has emerged as a pivotal innovation in enhancing operational efficiency across various industries. According to a report by MarketsandMarkets, the global solenoid valve market is projected to reach USD 6.84 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.6% during the forecast period. This growth is driven by the increasing demand for precise control in water management systems, particularly in sectors such as Agriculture, Manufacturing, and HVAC systems.

In the realm of modern automation, the deployment of water solenoid valves has emerged as a pivotal innovation in enhancing operational efficiency across various industries. According to a report by MarketsandMarkets, the global solenoid valve market is projected to reach USD 6.84 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.6% during the forecast period. This growth is driven by the increasing demand for precise control in water management systems, particularly in sectors such as Agriculture, Manufacturing, and HVAC systems.

Water solenoid valves facilitate seamless automation by allowing for the rapid opening and closing of water flow, significantly reducing the manual labor required for water regulation. As industries continue to integrate advanced technologies, understanding the functionality and application of water solenoid valves will be essential for harnessing their full potential and driving efficiency in automated processes.

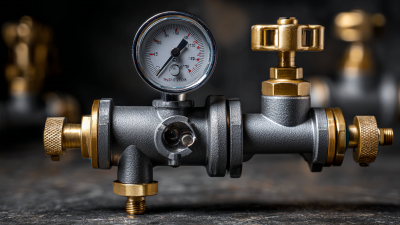

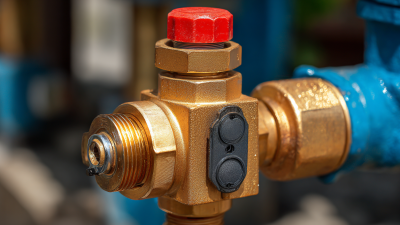

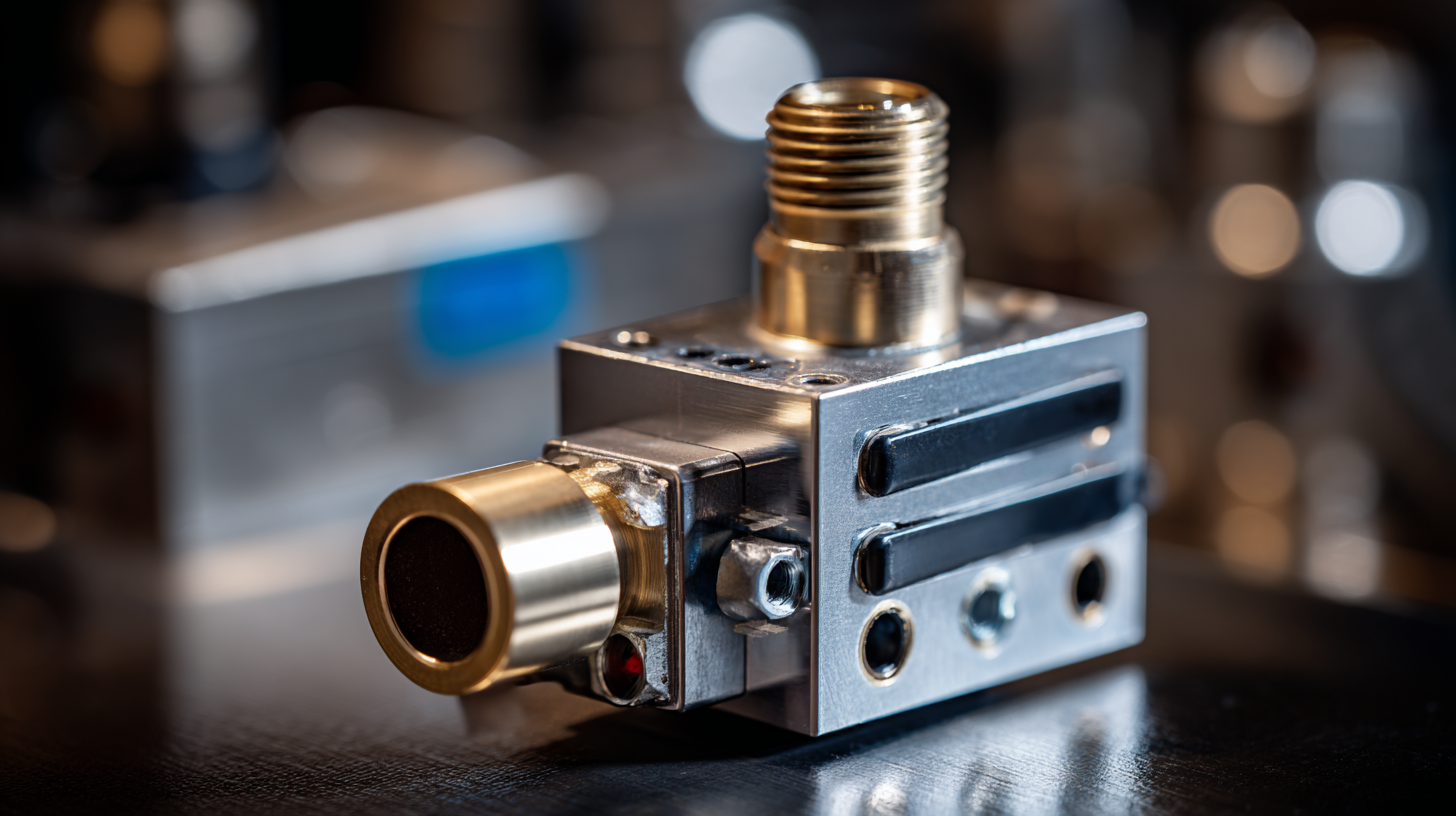

Water solenoid valves are crucial components in modern automation, controlling the flow of water in various applications such as irrigation systems, industrial processes, and home automation. These valves operate through an electromagnetic coil that opens or closes the valve when electrical current passes through it. When energized, the electromagnet creates a magnetic field that pulls a plunger, allowing water to flow. Conversely, when the current is turned off, the valve closes, stopping the water flow. This on-off mechanism provides precise control over water distribution, making it an indispensable part of automated systems.

Understanding the basic function of water solenoid valves reveals their versatility and efficiency in different settings. They come in various sizes and materials, making them adaptable for specific requirements, from high-pressure environments to delicate applications. Moreover, their quick response time enhances the automation process, reducing waste and improving overall system performance. By integrating water solenoid valves into automation systems, businesses can achieve greater efficiency and reliability, ultimately leading to optimized water management and resource conservation.

When selecting water solenoid valves for automation, several key features should be prioritized to ensure optimal efficiency and performance. First and foremost, the valve's flow rate and pressure rating must align with the specific application requirements. High flow rates may be necessary for certain industrial processes, while others may require more precise control at lower pressures. Additionally, consider the valve's size and configuration, as these factors can significantly affect installation and integration within existing systems.

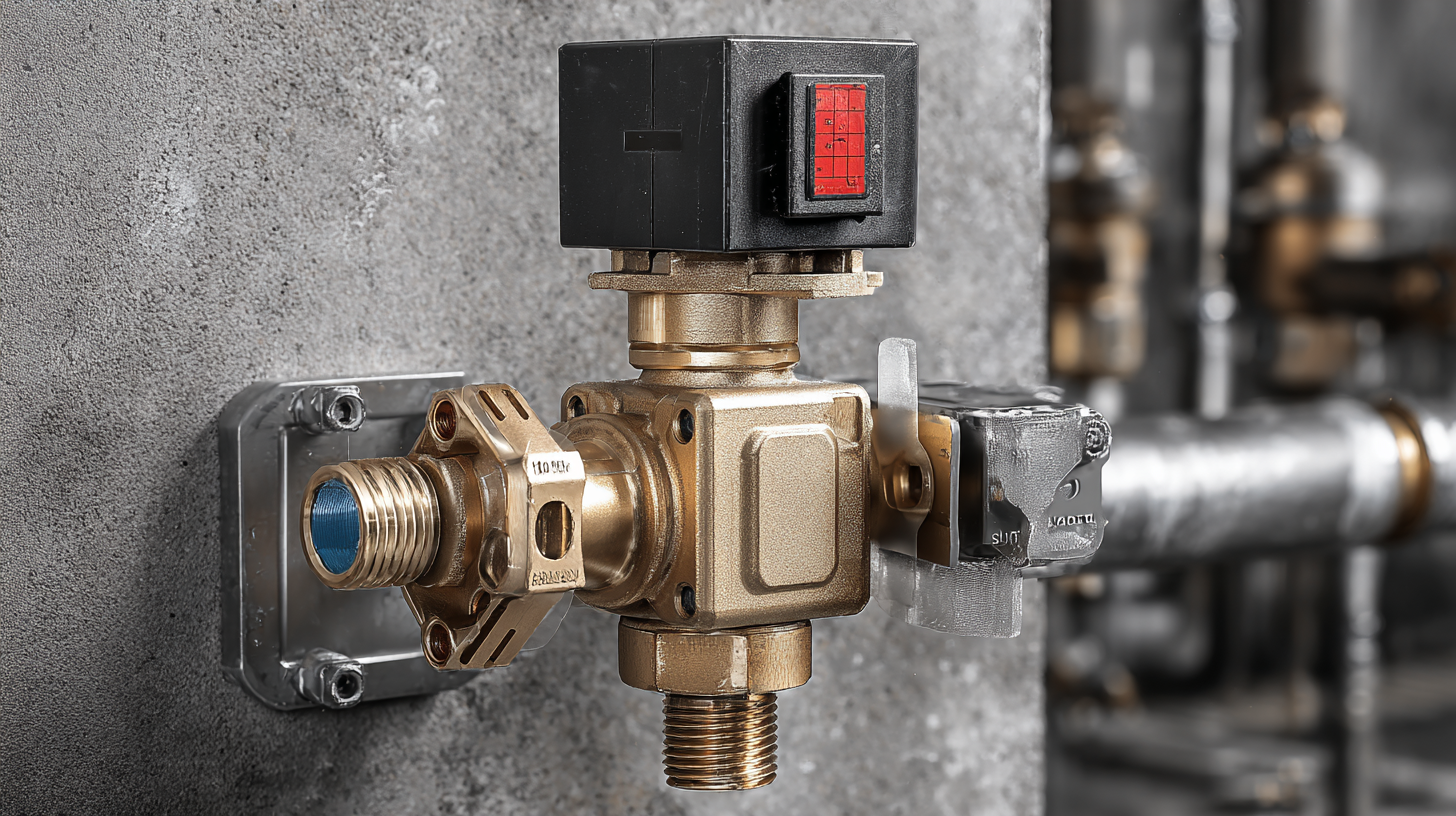

Another crucial element is the valve's construction material. Different environments may expose the valve to various chemicals, pressures, and temperatures, making it vital to choose materials that offer durability and resistance to corrosion. Common materials include brass, stainless steel, and plastic, each with its unique benefits for specific applications. Furthermore, you should evaluate the valve's electrical specifications, including voltage, power consumption, and actuation speed, to ensure compatibility with your automation system and to optimize energy usage.

Incorporating advanced features such as manual override, feedback mechanisms, and built-in diagnostics can enhance the functionality and reliability of solenoid valves in automated systems. These features help in maintaining control and reducing downtime during maintenance operations, ultimately contributing to a more efficient automation process. Therefore, thorough consideration of these elements will lead to a well-informed choice that meets the demands of modern automated environments.

When it comes to maximizing the performance of water solenoid valves in modern automation, proper installation is critical. Ensuring that these components are set up correctly can significantly affect their efficiency and lifespan. One key tip is to carefully check the alignment of the valve with the piping system; misalignment can lead to leaks or malfunctions. Using Teflon tape on the threads can help create a secure seal, minimizing the risk of water escaping during operation.

Another important aspect of installation is considering the electrical connections. Ensure that the wiring is appropriately sized for the application and that all connections are tight to prevent any shorts or disconnections. Additionally, it's wise to install the valve in a location that is easily accessible for maintenance and inspections. This not only extends the life of the solenoid valve but also allows for quicker troubleshooting if issues arise. By following these installation tips, users can ensure that their water solenoid valves operate at peak efficiency and reliability.

Water solenoid valves play a crucial role in automated systems, controlling the flow of water with precision and efficiency. However, like any mechanical component, they can encounter several common issues that may disrupt operations. One such problem is the valve not opening or closing properly, which could be due to electrical faults, such as burnt-out coils or loose connections. Regular maintenance checks are essential to ensure that all electrical components are functioning as intended.

Another frequent issue is leakage, which can arise from wear and tear of seals or improper installation. It's vital to inspect the valve and its surrounding connections regularly to identify potential leaks before they lead to significant problems. Additionally, solenoid valves may also be affected by debris or sediment build-up, which can hinder their performance. Utilizing filters and performing periodic cleaning can help maintain optimal functionality, ensuring that the solenoid valves operate effectively within automated systems. By addressing these common issues proactively, users can enhance the reliability and efficiency of their automated water control systems.

Water solenoid valves play a crucial role in modern irrigation systems, particularly as agricultural practices continue to evolve toward more efficient and automated solutions. With water scarcity affecting semi-arid regions, the effective utilization of these valves can significantly enhance irrigation management. For instance, implementing a wireless sensor network can optimize the performance of drip irrigation systems by precisely controlling water flow. According to industry reports, the global agricultural irrigation market is projected to reach billions, underscoring the importance of such technological advancements in improving water use efficiency.

Maintaining water solenoid valves is essential to ensure their longevity and operational efficiency. Best practices include regular inspection and cleaning to prevent debris accumulation, which can lead to valve malfunction. A systematic reliability-centered maintenance framework has been developed, demonstrating its effectiveness in the manufacturing process machinery sector, which can be adapted for agricultural applications. Moreover, hybrid irrigation systems that incorporate IoT sensors for real-time monitoring have shown significant promise in enhancing water distribution accuracy, affirming that smart maintenance and technology integration are key to achieving sustainable water management in agriculture.

| Aspect | Recommended Action | Frequency | Notes |

|---|---|---|---|

| Inspection | Check for leaks and corrosion | Monthly | Early detection can prevent major failures. |

| Cleaning | Clean valve surfaces and surrounding areas | Quarterly | Helps maintain proper function and appearance. |

| Lubrication | Apply lubricant on moving parts | Every 6 months | Reduces wear and extends life of the valve. |

| Testing | Conduct functional tests for operation | Annually | Ensures the system operates under desired conditions. |

| Parts Replacement | Replace worn or damaged components | As needed | Prolongs the lifespan and efficiency of the valve. |