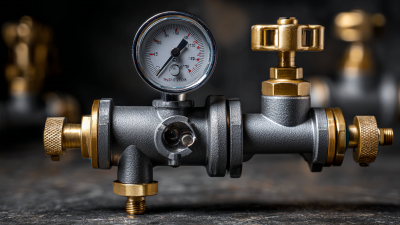

In today's fast-paced industrial landscape, optimizing workflow efficiency is crucial for maintaining competitive advantage. One key component that can significantly enhance system performance is the pressure regulator valve. These devices play a vital role in controlling and maintaining the desired pressure levels within various systems, ensuring that operations run smoothly and efficiently. By effectively managing pressure, pressure regulator valves not only prevent equipment damage but also contribute to energy savings and improved process reliability. In this blog, we will explore the benefits of implementing pressure regulator valves in your operations, discussing how they can streamline workflows, reduce downtime, and ultimately lead to increased productivity and cost-effectiveness.

Pressure regulator valves play a crucial role in optimizing workflows across various industries by maintaining consistent pressure levels within systems. These valves ensure that equipment operates at optimal performance by regulating the pressure of liquids and gases. By preventing pressure fluctuations, they minimize potential damages to machinery and improve overall efficiency. Properly calibrated pressure regulator valves can also enhance safety by reducing the risk of overpressure scenarios that could lead to system failures.

In addition to protecting equipment, pressure regulator valves contribute to energy savings and reduced operational costs. By regulating the flow and pressure more precisely, they help to streamline processes and eliminate waste. This not only leads to a more sustainable operation but also allows companies to redirect resources towards innovation and growth. Understanding the specific needs of your system and selecting the right pressure regulator valve can significantly enhance productivity and reliability in your workflow, making it an essential component of any efficient system design.

Efficiency in pressure management is critical for any system relying on fluid dynamics. Key Performance Indicators (KPIs) serve as benchmarks to assess how effectively pressure regulator valves are functioning within your workflow. Metrics like pressure drop, flow rate consistency, and response time can reveal areas needing improvement. Tracking these indicators regularly allows for proactive adjustments, ultimately leading to enhanced system performance.

Tips: Regularly monitor the pressure drop across your valves to ensure they are operating within optimal parameters. A significant drop might indicate blockage or wear, requiring immediate attention. Additionally, maintaining a consistent flow rate is essential; fluctuations can lead to inefficiencies in processes and compromise system integrity.

Another important KPI to consider is the response time of your pressure regulator valves. By measuring how quickly a valve reacts to pressure changes, you can evaluate its effectiveness. If response times are sluggish, this could hinder overall workflow efficiency. Implementing routine testing and investing in high-quality valves can significantly enhance response capabilities, boosting productivity across your systems.

In many industries, operational costs can significantly be influenced by the efficiency of system components, with pressure regulator valves playing a crucial role. These valves not only help maintain optimal pressure levels but also contribute to minimizing energy consumption and reducing wear and tear on equipment. By fine-tuning the pressure, businesses can enhance their workflow and lower overall operational expenses.

In many industries, operational costs can significantly be influenced by the efficiency of system components, with pressure regulator valves playing a crucial role. These valves not only help maintain optimal pressure levels but also contribute to minimizing energy consumption and reducing wear and tear on equipment. By fine-tuning the pressure, businesses can enhance their workflow and lower overall operational expenses.

Tip: Regularly monitor and calibrate your pressure regulator valves to ensure they are operating within their optimal range. This will not only prolong the lifespan of your equipment but also prevent unnecessary energy expenditure.

Furthermore, implementing industry benchmarks for pressure regulators can provide invaluable insights into improving efficiency. Adapting these standards allows companies to identify areas where they can reduce waste and optimize processes. By analyzing how pressure regulators impact production rates and utility costs, organizations can make informed adjustments that yield substantial savings.

Tip: Conduct routine evaluations of your pressure regulation systems against industry benchmarks. This proactive approach will help you stay competitive and align your operations with best practices.

Implementing pressure regulator valves can significantly enhance workflow efficiency across various industries. By examining successful case studies, we can see how these valves have transformed operations in real-world settings. For instance, a manufacturing company faced recurring issues of fluctuating pressure, which led to inconsistent product quality. By integrating pressure regulator valves into their system, they achieved stable pressure levels, resulting in a marked improvement in product consistency and a reduction in waste.

One critical tip for selecting the right pressure regulator valve is to assess the specific requirements of your system. Consider factors such as pressure range, flow rate, and the type of media being controlled. This ensures that the chosen valve effectively meets operational needs and optimizes performance.

Another important consideration is regular maintenance. Ensuring that pressure regulator valves are properly maintained can prevent system inefficiencies and costly downtime. Implementing a routine inspection schedule can help identify potential issues before they escalate, maintaining smooth operations and contributing to overall productivity.

Innovative technologies are revolutionizing the way pressure regulation is managed in workflow systems. By integrating advanced pressure regulator valves, organizations can significantly enhance their operational efficiency and overall productivity. These valves not only provide precise control over pressure levels but also enable real-time adjustments that adapt to varying system demands. The shift towards smart manufacturing means that these technologies are becoming more accessible and affordable, allowing businesses of all sizes to optimize their workflow.

**Tip:** When selecting pressure regulator valves for your workflow system, consider opting for models with built-in sensors and digital monitoring capabilities. This feature will allow you to collect data on pressure fluctuations and identify potential areas for improvement, leading to more informed decision-making.

Furthermore, the emergence of IoT technology in pressure regulation has led to the development of automated systems that minimize human intervention. These innovations help to reduce the risk of errors and ensure compliance with safety standards, ultimately creating a more reliable working environment.

**Tip:** Implement regular training sessions for your staff to familiarize them with the latest pressure regulation technologies. This will empower them to utilize these systems more effectively, and integrate best practices for maintenance and operation, thus maximizing the benefits of your investment.

| System Type | Pressure Range (psi) | Flow Rate (GPM) | Material | Applications |

|---|---|---|---|---|

| Hydraulic Systems | 1000 - 3000 | 15 | Aluminum | Construction, Manufacturing |

| Pneumatic Systems | 50 - 150 | 10 | Brass | Automotive, Food Processing |

| Water Supply Systems | 20 - 80 | 5 | PVC | Municipal, Agricultural |

| Industrial Gases | 200 - 500 | 7 | Stainless Steel | Chemicals, Manufacturing |

| Steam Systems | 150 - 900 | 12 | Cast Iron | Energy, Food Processing |