In today's rapidly evolving technological landscape, the challenge of efficiently managing water flow has become increasingly paramount for various industries, from agriculture to manufacturing. One of the most effective tools in achieving precise water control is the water solenoid valve. This innovative device allows for automated regulation of water flow, ensuring that systems function optimally while conserving resources. As water scarcity becomes a pressing global issue, implementing advanced solutions like water solenoid valves is not just beneficial but necessary.

In this blog post, we will explore the top strategies for effectively utilizing water solenoid valves, highlighting their features, benefits, and best practices to maximize their efficiency in water management systems. With the right approach, organizations can enhance operational efficiency, reduce waste, and contribute to sustainable resource management.

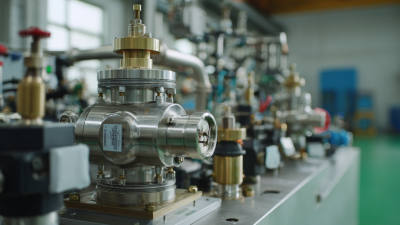

Water solenoid valves are increasingly recognized as essential components for efficient flow control in various applications, including irrigation, wastewater management, and industrial processes. According to a report by Research and Markets, the global solenoid valve market is projected to reach $2.95 billion by 2025, driven largely by the rising demand for automation and precision in fluid management systems. This growth underscores the significant role water solenoid valves play in enhancing operational efficiency and reducing waste.

One of the major benefits of using water solenoid valves is their ability to provide quick and precise control over water flow. These valves can be actuated within milliseconds, allowing for rapid response times in systems that require immediate adjustments in flow rates. A study by the American Society of Agricultural and Biological Engineers indicates that implementing solenoid valves in irrigation systems can lead to a 20-30% reduction in water usage. This capability not only conserves water but also optimizes resource management, making solenoid valves a smart choice for sustainable practices in agriculture and other sectors.

Water solenoid valves play a critical role in managing water flow across various applications, from agricultural irrigation to industrial processes. Understanding the types of water solenoid valves and their applications is essential for optimizing their use. Among the commonly utilized types are normally open and normally closed valves, each serving specific purposes. Normally closed valves prevent water flow until activated, making them ideal for applications requiring precise control, while normally open valves allow flow until deactivated and are suitable for systems where constant flow is necessary.

When selecting water solenoid valves, it's essential to consider factors such as operating pressure, the material of the valve, and the specific application environment. For instance, in food and beverage applications, certification for safe water usage is crucial, ensuring compliance with health standards. Additionally, the latest advancements in valve technology, such as innovative sealing structures, aim to enhance operational efficiency and reliability under varying conditions.

**Tips:** Ensure that the solenoid valve's specifications match your application requirements, particularly in high-pressure environments. Always opt for valves that are certified for your specific use to avoid any regulatory issues. Regular maintenance and monitoring of valve performance can also help prevent leaks and operational failures, prolonging the life of your water management system.

| Type of Solenoid Valve | Application | Operating Voltage | Fluid Type | Flow Rate |

|---|---|---|---|---|

| Normally Closed | Irrigation Systems | 12V DC | Water | 0.5 to 2.0 L/min |

| Normally Open | Aquarium Systems | 24V AC | Freshwater/Saltwater | 0.3 to 1.5 L/min |

| Latching Solenoid | Industrial Automation | 5V DC | Water/Oil | 2.0 to 10.0 L/min |

| Pilot Operated | HVAC Systems | 220V AC | Water | 5.0 to 20.0 L/min |

| High-Pressure Solenoid | Agricultural Applications | 12V DC | Water | 1.0 to 15.0 L/min |

When selecting water solenoid valves for efficient control of water flow, several key features must be considered to ensure optimal performance and longevity. One crucial factor is the valve's flow rate, typically measured in gallons per minute (GPM). According to industry reports, solenoid valves with a higher flow rate can significantly improve system efficiency, reducing the time needed for water to reach its destination. Valves designed for specific applications can handle varying pressures and flow requirements, making them essential for agricultural irrigation systems, industrial processing, and residential water management.

Another important consideration is the material composition of the solenoid valve, as this directly impacts durability and resistance to corrosion. Materials like brass and stainless steel are commonly recommended for their strength and chemical resistance. The Global Market Insights report indicates a rising trend in the use of durable materials in solenoid valve manufacturing, projecting a compound annual growth rate (CAGR) of over 5% in this segment through 2027. Additionally, selecting a valve with appropriate voltage ratings ensures compatibility with the existing electrical systems, minimizing the risk of failure and enhancing operational reliability. Thus, investing time into evaluating these features will lead to improved efficiency and reduced maintenance costs in fluid control systems.

Smart irrigation systems are revolutionizing the way we manage water resources, and integrating water solenoid valves into these systems significantly enhances their efficiency. These valves function as automated control devices that regulate the flow of water based on real-time soil moisture levels or weather data. By employing water solenoid valves, farmers and gardeners can ensure that their plants receive the precise amount of water needed for optimal growth without the waste often associated with traditional irrigation methods.

Moreover, the integration of solenoid valves allows for remote monitoring and control through smart devices. This connectivity empowers users to adjust irrigation schedules and flow rates from anywhere, ensuring that irrigation is not only efficient but also environmentally friendly. With the ability to program specific watering times and durations, these systems reduce water consumption, lower utility bills, and contribute to sustainable practices in agricultural management. As technology advances, the role of water solenoid valves in smart irrigation continues to grow, making them an essential component for those seeking to optimize water usage.

Maintaining solenoid valves is crucial for ensuring optimal performance and efficient control of water flow. Regular inspection and cleaning can help prevent issues such as air contamination, which can significantly affect valve functionality. A recent industry report highlights that up to 30% of valve failures can be attributed to contamination within pneumatic systems. Therefore, proper maintenance practices are essential for extending the lifespan of solenoid valves.

Tip 1: Schedule regular maintenance checks for your solenoid valves. This includes cleaning the valves and checking for signs of wear or damage. According to market analysts, proactive maintenance can reduce operational costs by up to 25%.

Tip 2: Utilize advanced monitoring technologies to enhance valve performance. The introduction of smart valve connectors can facilitate continuous communication with pneumatic systems, enabling real-time diagnostics and streamlining maintenance efforts.

Incorporating these maintenance tips not only improves the reliability of solenoid valves but also optimizes water flow control in various applications. Regular upkeep ensures that systems operate efficiently and reduces the risk of unexpected downtime.