In the realm of modern industrial systems, the efficiency and functionality of components play a crucial role in optimizing operations and maintaining safety standards. One such component that has gained significant attention is the plug valve. Known for its simple design and reliable performance, the plug valve is essential in applications requiring quick shutoff and precise flow control. This article delves into the various aspects of plug valves, exploring their working principles, advantages, and suitable applications across different industries. Understanding the efficiency and versatility of plug valves not only aids in selecting the right type for specific needs but also highlights their importance in enhancing operational efficiency and reducing downtime in industrial processes. Join us as we explore the intricacies of plug valves and their vital role in contemporary industrial settings.

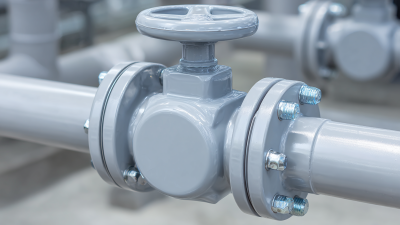

Plug valves are widely recognized for their efficiency in modern industrial systems, utilizing a cylindrical or tapered plug to control fluid flow. The primary efficiency metrics of plug valves revolve around their ability to minimize pressure drops, handle high flow rates, and provide a tight seal. These characteristics make them particularly suitable for applications requiring quick shut-off and reliable operation in harsh environments.

When assessing the efficiency of plug valves, one must consider factors like flow coefficient (Cv) and leakage rates. A higher Cv indicates that the valve can allow more fluid to pass through at a given pressure drop, enhancing operational efficiency. Additionally, high-quality materials used in valve construction can further reduce wear and tear, ensuring longevity and optimal performance.

**Tips:** Ensure that you select the appropriate size and type of plug valve for your specific application to maximize efficiency. Regular maintenance, including routine inspections and proper lubrication, can significantly extend the life of your plug valves. Furthermore, consider using lined or coated valves if your application involves corrosive substances to maintain both efficiency and integrity.

Plug valves, gate valves, and ball valves, each serve distinct roles in industrial applications, influenced by their design efficiencies and operational capabilities. A comparative analysis reveals that plug valves are ideal for applications requiring tight sealing and rapid flow control due to their simple quarter-turn operation. In contrast, gate valves are more suited for on/off services where minimal pressure drop is crucial, while ball valves provide excellent closure and low resistance to flow, making them popular in various sectors including oil and gas, water treatment, and chemical manufacturing.

According to a recent report on the ball valve market, it is anticipated to reach a notable size and share, driven by increasing industrial automation and the demand for effective fluid control systems. Specifically, market segments based on materials such as stainless steel and alloy-based designs are experiencing growth due to their superior durability and resistance to corrosive environments. Furthermore, advancements in technology, like vibration analysis for fault detection in control valves, showcase the industry's push towards enhanced reliability and predictive maintenance, ensuring operational efficiency across modern industrial systems.

When evaluating the lifecycle costs of plug valves in various industries, it’s essential to consider key factors such as installation, maintenance, and operational efficiency. Plug valves are favored for their simplicity and low-pressure drop, making them suitable for a range of applications from oil and gas to wastewater management. However, the initial purchase price is just one part of the equation. Long-term maintenance costs, including potential repairs and replacements due to wear, should also be factored into the total cost assessment.

**Tips:** Regular inspections and scheduled maintenance can significantly extend the lifespan of plug valves, reducing overall costs. It’s advisable to choose valves made from materials that are compatible with the process fluids to minimize corrosion and wear, ultimately leading to lower lifecycle expenses.

Furthermore, the operational environment can drastically impact the efficiency and durability of plug valves. Industries that deal with high levels of contaminants or require frequent cycling may experience more wear and tear, which can result in increased maintenance costs. Therefore, conducting a thorough lifecycle cost assessment—as well as evaluating the specific needs of your industry—can lead to more informed decisions, ensuring optimal performance and cost-effectiveness over time.

**Tips:** Investing in training for operational staff on the correct use and maintenance of plug valves can prevent common issues and reduce costs associated with improper handling.

The material selection for plug valves plays a crucial role in determining their overall performance in industrial systems. Different materials exhibit varying levels of resistance to corrosion, abrasion, and temperature fluctuations, which are common challenges in many applications. For instance, stainless steel valves are preferable in environments where corrosion is a major concern, while materials like PVC or PTFE can be advantageous in chemical processing due to their excellent resistance to aggressive substances. The choice of material not only affects the durability of the valve but also its sealing ability and flow characteristics.

Furthermore, the design and construction of the plug valve are closely linked to the properties of the selected materials. A well-designed plug valve made from high-quality materials can enhance efficiency, reduce maintenance costs, and extend the lifecycle of the system it operates within. In high-pressure applications, for example, the material must withstand significant stress without compromising the valve's integrity. Thus, understanding the implications of material selection allows engineers to optimize valve performance and ensure compatibility with specific operational conditions, ultimately leading to more reliable and efficient industrial processes.

| Material Type | Common Applications | Operating Temperature Range (°C) | Pressure Rating (PSI) | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Brass | Water Supply, Wastewater Treatment | -20 to 120 | 150 | Corrosion Resistant, Good for Low/Medium Pressure | Not suitable for high temperatures, Can corrode in aggressive environments |

| Stainless Steel | Chemical Processing, Oil & Gas | -50 to 300 | 300 | Durable, High Temperature and Pressure Resistance | Higher cost, Requires maintenance to prevent pitting |

| PVC | Water Pipelines, Irrigation Systems | 0 to 60 | 100 | Lightweight, Easy Installation | Limited temperature and pressure ratings, Can degrade under UV light |

| Ductile Iron | Wastewater Treatment, Fire Protection | -20 to 120 | 250 | Strong, Shock Resistant | Heavy, Susceptible to corrosion if not coated |

Recent advancements in technology have substantially improved the functionality and efficiency of plug valves, which are essential components in modern industrial systems.

According to a market research report by Transparency Market Research, the global valve market is projected to grow from USD 62.6 billion in 2022 to USD 87.3 billion by 2031, with plug valves playing a pivotal role due to their versatility and reliability in various applications. Innovations such as enhanced materials and smart sensor integrations are enabling plug valves to operate under extreme conditions while ensuring precise control of flow rates.

Moreover, the implementation of electronically controlled systems has heightened the efficiency of plug valves. A report from Grand View Research indicates that the demand for automated valves is expected to rise significantly, reflecting a growing trend towards energy-efficient operations in industrial processes. These innovations not only reduce maintenance costs but also prolong the service life of the valves, thereby promoting sustainability within manufacturing processes. As industries increasingly prioritize efficiency, the role of advanced plug valves will undoubtedly expand, driving further technological developments and operational enhancements in the field.