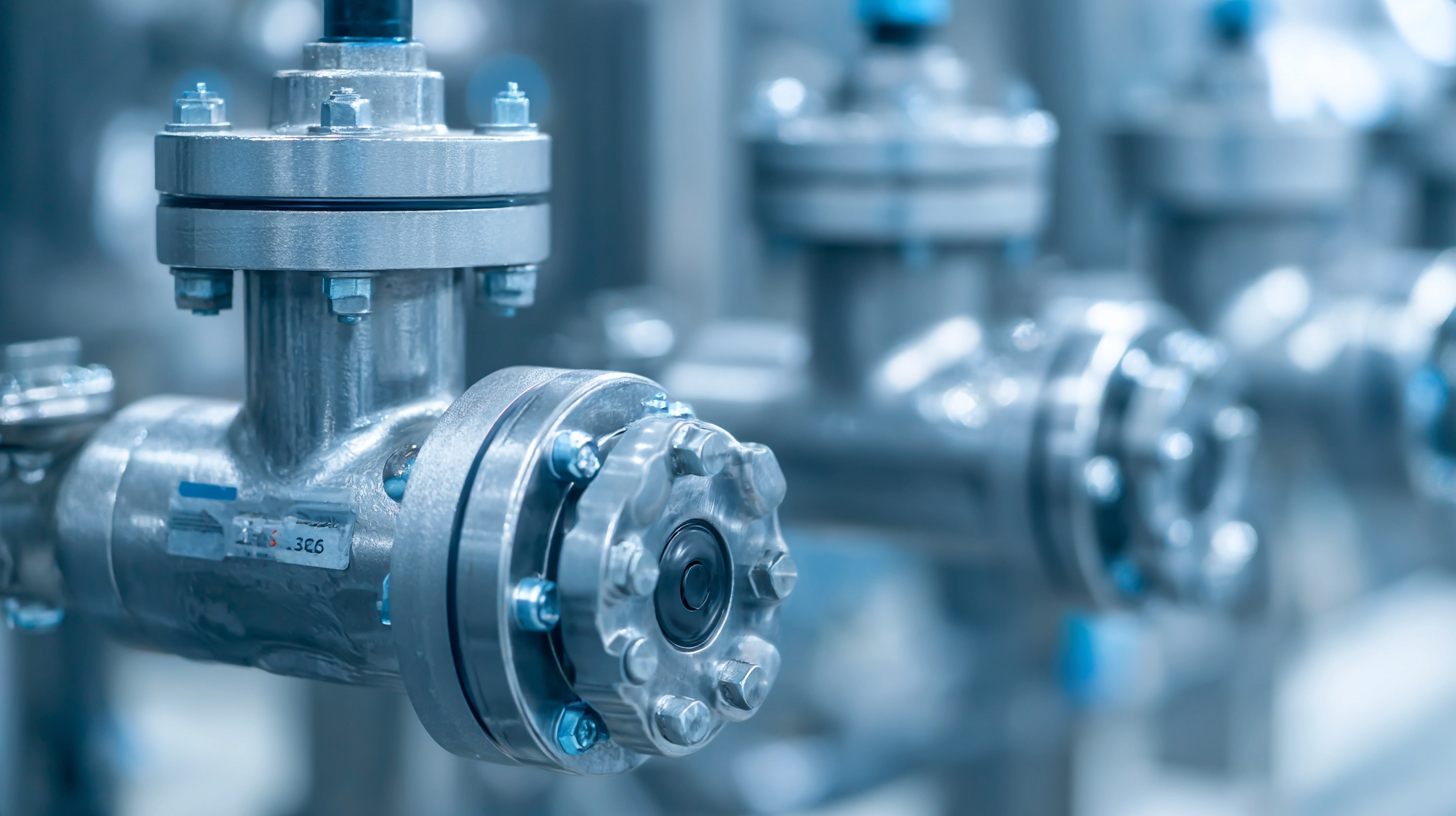

Diaphragm valves have become increasingly essential in modern fluid control systems, driven by the growing demand for precision and reliability across various industries, such as pharmaceuticals, food and beverage, and chemical processing. According to a recent market research report by Fortune Business Insights, the diaphragm valves market is projected to reach USD 7.14 billion by 2028, growing at a CAGR of 5.8% from 2021 to 2028. This growth is fueled by their unique design that allows for dead-end service advantages and minimizes the risk of contamination, a crucial factor for maintaining product integrity in sensitive applications.

Additionally, diaphragm valves are renowned for their ability to handle corrosive media and abrasive slurries, which significantly enhances their utility in complex industrial environments. Understanding the key applications and benefits of diaphragm valves is vital for engineers and decision-makers aiming to optimize fluid control processes while adhering to stringent regulatory standards.

Additionally, diaphragm valves are renowned for their ability to handle corrosive media and abrasive slurries, which significantly enhances their utility in complex industrial environments. Understanding the key applications and benefits of diaphragm valves is vital for engineers and decision-makers aiming to optimize fluid control processes while adhering to stringent regulatory standards.

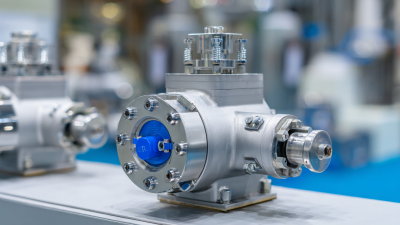

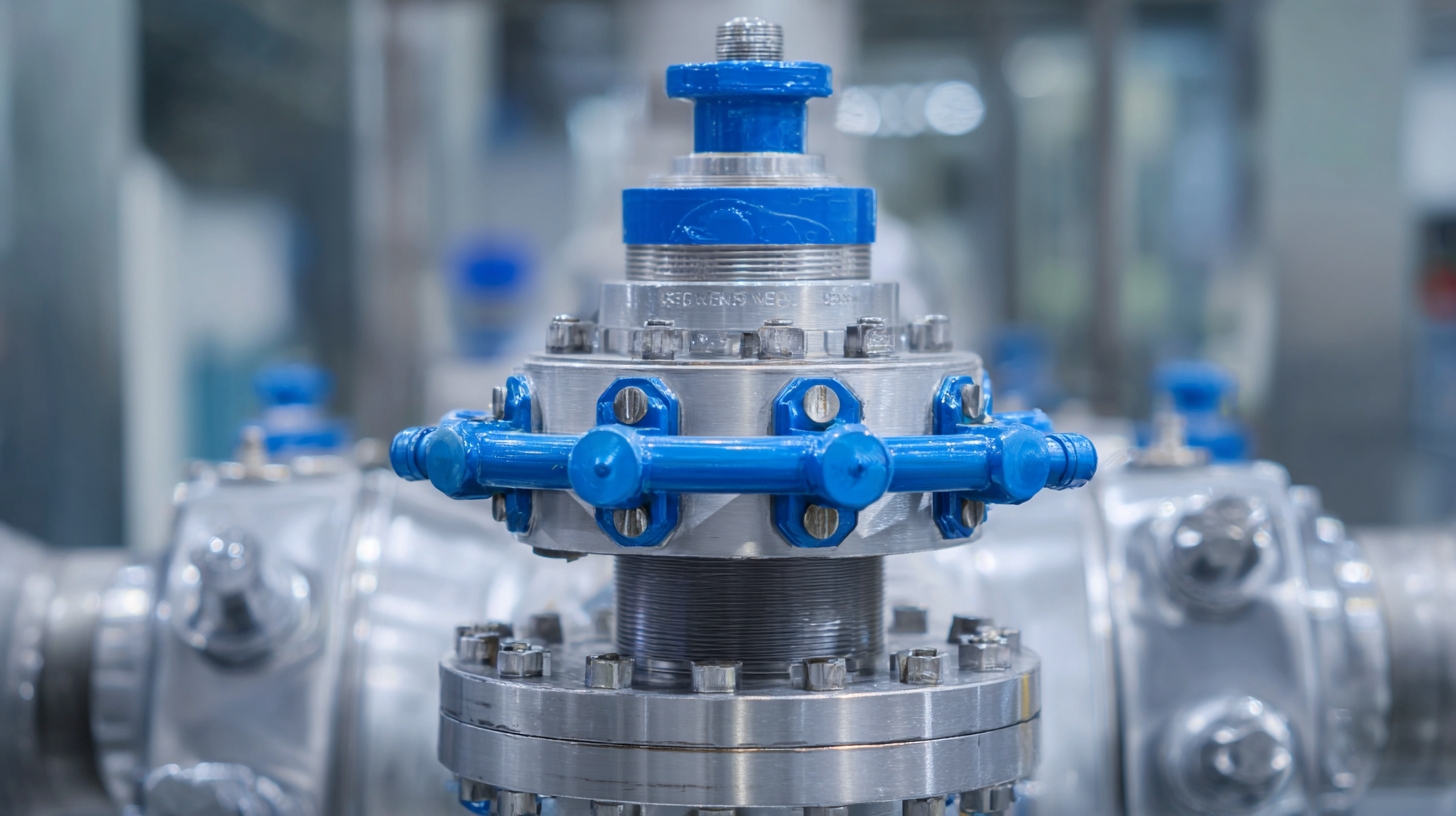

Diaphragm valves play a crucial role in modern fluid control systems, primarily due to their unique construction and operational characteristics. These valves utilize a flexible membrane (the diaphragm) to regulate flow, which ensures a tight seal and minimal leakage. According to a recent market report by Research and Markets, the global diaphragm valve market is projected to grow at a CAGR of 5.2% through 2026, driven by increasing demands in sectors such as water treatment, pharmaceuticals, and food processing. This growth highlights the reliability and efficiency that diaphragm valves bring to fluid management.

One of the key characteristics of diaphragm valves is their ability to handle corrosive and viscous fluids, making them suitable for diverse applications. Their uncomplicated design allows for easy maintenance and cleaning, which is essential in industries where hygiene is paramount. Furthermore, diaphragm valves can operate in a wide temperature range, adapting to various industrial environments without compromising performance. A report from the Valve Manufacturers Association notes that diaphragm valves are especially favored in pharmaceutical applications, where sterility and precision are critical, as they reduce the risk of contamination compared to traditional valves. This adaptability and reliability make diaphragm valves an essential component in sophisticated fluid control systems.

Diaphragm valves are increasingly recognized for their versatility and efficiency in various industrial applications, equipping sectors with superior fluid control capabilities. These valves are particularly prominent in the pharmaceutical, food and beverage, biotechnology, and wastewater treatment industries. According to a recent report by MarketsandMarkets, the global diaphragm valve market is projected to reach $3 billion by 2026, highlighting the growing reliance on these devices for precise flow control and reduced chances of contamination.

One of the top applications for diaphragm valves is in the pharmaceutical industry, where maintaining sterile conditions is critical. These valves offer efficient throttling and on-off control, allowing manufacturers to handle corrosive and pure liquids without risk of leakage. Similarly, in the food and beverage sector, diaphragm valves facilitate hygienic processes and comply with strict FDA regulations, making them a preferred choice for many operations.

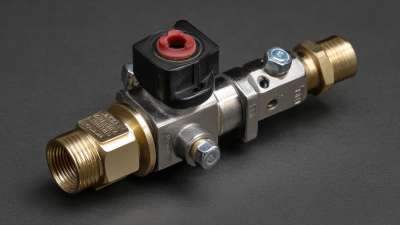

Tips: When selecting a diaphragm valve for a specific application, consider factors such as material compatibility, pressure requirements, and ease of maintenance. Regular inspection and maintenance can significantly extend the life of diaphragm valves, particularly in high-demand environments. Additionally, consult with manufacturers regarding customization options to meet unique operational needs.

Diaphragm valves offer several advantages over traditional valve types, making them an increasingly popular choice in various industrial applications. One of the key benefits is their ability to provide a tight seal, which minimizes the risk of leakage. This is particularly important in industries such as pharmaceuticals and food processing, where contamination must be avoided at all costs. The elastomeric diaphragm effectively isolates the fluid from the actuator and other components, ensuring high levels of hygiene and safety.

Another significant advantage of diaphragm valves is their versatility in handling corrosive and abrasive fluids. Unlike traditional metal valves, diaphragm valves can be constructed with non-corrosive materials, enabling them to withstand harsh environments. Furthermore, they require less maintenance due to their design, which reduces wear and tear over time. This not only leads to increased operational efficiency but also contributes to cost savings in the long run. Overall, diaphragm valves are favored for their reliability, ease of use, and superior performance in demanding fluid control applications.

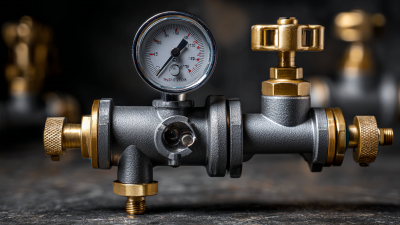

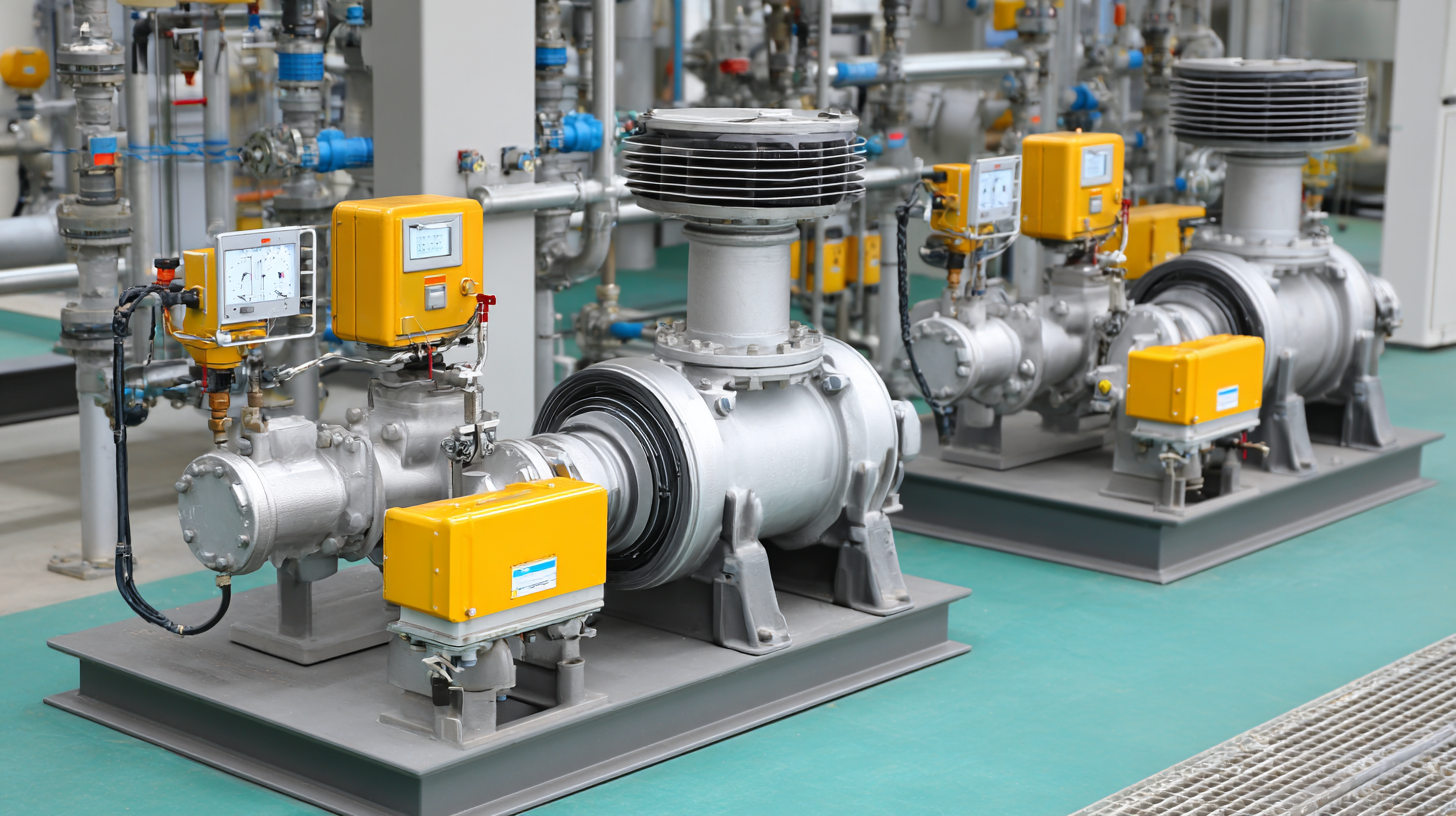

Maintaining and operating diaphragm valves effectively is crucial for optimizing fluid control systems across various industries. Best practices involve regular inspections, ensuring that seals and diaphragm materials are compatible with the fluids they handle, and performing periodic testing to verify operability. Operators should also monitor pressure management systems at key locations, which may include the installation of hydraulic pressure control valves. This proactive approach not only enhances operational efficiency but can also prevent downtime due to unexpected valve failures.

When it comes to diaphragm pumps, understanding their working mechanisms is essential for their efficient operation. Regular maintenance should include checking for wear and tear on diaphragms and seals, as well as ensuring that all connections are secure. Moreover, conducting routine fluid quality assessments can help identify potential contamination issues that could compromise pump performance. By implementing these best practices, industries can harness the full potential of diaphragm valves and pumps, driving not only operational savings but also contributing to overall system integrity.

The diaphragm valve market is experiencing transformative trends driven by advancements in technology and the increasing demands of various industries. According to a recent market report by Research and Markets, the global diaphragm valve market is projected to grow at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is largely propelled by innovations such as automated diaphragm valves, which enhance precision and reduce manual intervention, thereby increasing operational efficiency.

Moreover, the integration of smart technology into diaphragm valves is revolutionizing fluid control systems. The advent of IoT-enabled valves allows for real-time monitoring and predictive maintenance, significantly minimizing downtime and operational costs. A report by MarketWatch indicates that the IoT in the industrial sector is expected to reach a market value of $1 trillion by 2026, underscoring the importance of intelligent systems in driving the future of fluid control. As industries continue to prioritize efficiency and sustainability, diaphragm valve technologies incorporating these innovations are well-positioned to meet evolving market demands and enhance fluid management processes.