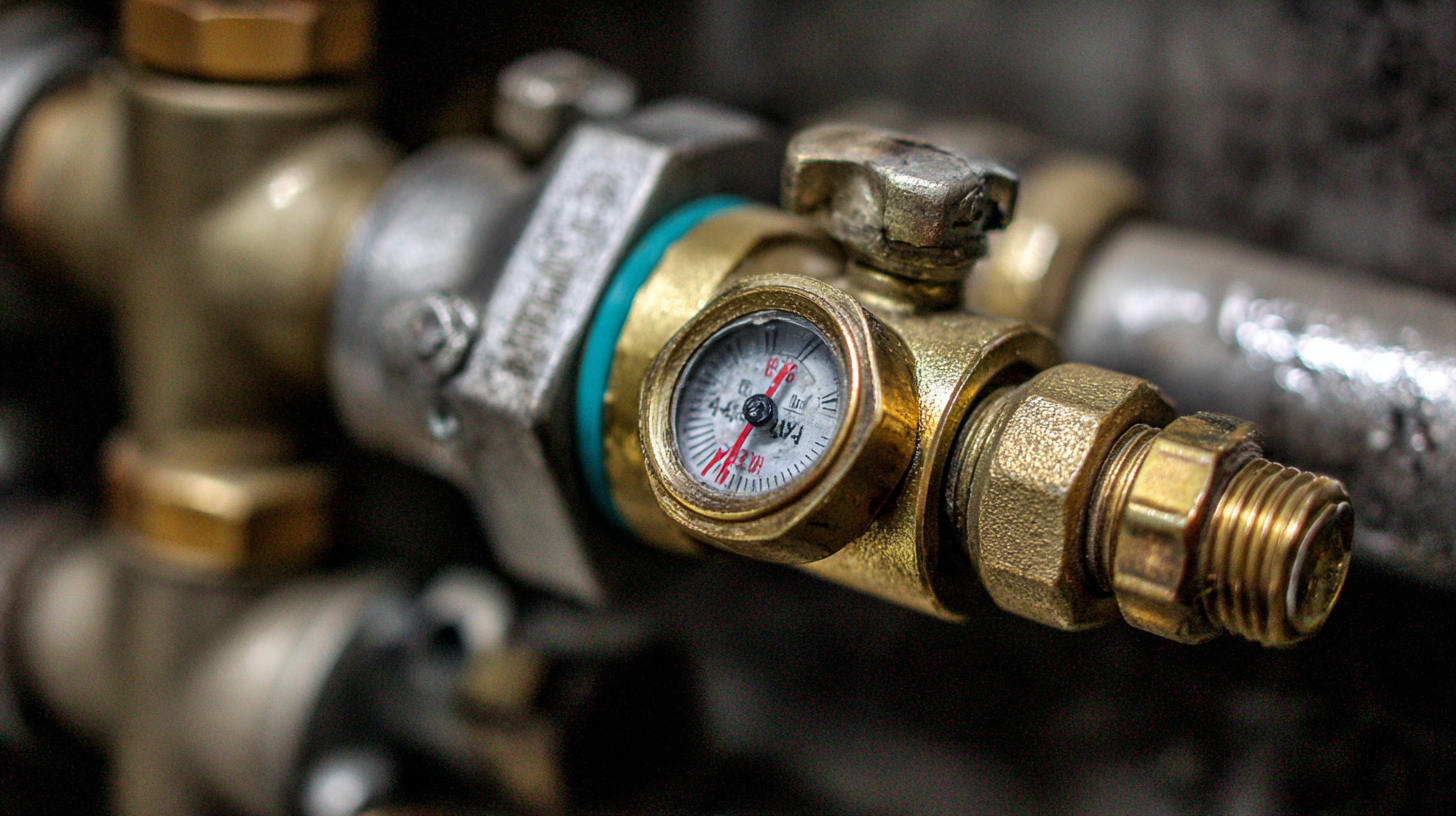

In today's rapidly evolving industrial landscape, the importance of selecting the right pressure regulator valve cannot be overstated. According to a recent report by MarketsandMarkets, the pressure regulator market is expected to grow from USD 2.8 billion in 2020 to USD 4.1 billion by 2025, showcasing an increase in demand for efficient pressure management solutions across various sectors. A pressure regulator valve is essential for maintaining consistent pressure in systems, ensuring optimal performance, safety, and longevity of equipment. However, with numerous options available, choosing the best regulator can be daunting. This guide aims to equip you with the necessary knowledge and insights to make an informed decision, while highlighting key factors such as material compatibility, pressure range, and application specifics that directly impact the effectiveness of a pressure regulator valve in your operations.

Pressure regulator valves are essential components in various systems where maintaining a consistent pressure is critical. These devices play a crucial role in controlling the pressure of fluids, ensuring that it remains within set parameters to protect equipment and optimize performance. By automatically adjusting the pressure based on downstream demands, these valves prevent fluctuations that could lead to equipment damage or inefficient operation.

One of the key functions of pressure regulator valves is their ability to enhance safety. In applications such as gas distribution or water systems, excessive pressure can pose significant hazards. A well-chosen pressure regulator valve can mitigate these risks by preventing pressure surges and maintaining a safe operating environment. Additionally, the benefits extend to improving efficiency and reducing operational costs by ensuring that systems are not over-pressurized, leading to lower energy consumption and prolonging the lifespan of system components. Thus, understanding the core functions and advantages of pressure regulator valves is vital when selecting the right one for specific applications.

| Feature | Description | Benefits |

|---|---|---|

| Pressure Range | Typically measured in PSI or bar, indicating the allowable pressure limits. | Ensures that the system operates safely and efficiently within specified limits. |

| Flow Rate | The volume of fluid that can pass through the valve, usually measured in GPM or L/min. | Ensures adequate supply for the application, improving overall efficiency. |

| Body Material | Common materials include brass, stainless steel, and plastic. | Durability and compatibility with various fluids and environments. |

| Adjustment Type | Can be manual or automatic, affecting ease of use and precision. | Allows for fine-tuning of pressure settings based on application needs. |

| Temperature Rating | Indicates the maximum and minimum operational temperatures. | Ensures reliable performance in varying environmental conditions. |

When selecting a pressure regulator valve, it's crucial to identify specific needs before making a decision. According to the Flow Control Industry Report 2023, the accuracy and reliability of pressure control devices play a vital role in enhancing system efficiency. Factors such as the type of fluid, pressure range, and flow rate should be carefully assessed. For instance, industrial applications often require regulators that can handle high pressures up to 6000 psi, while residential settings may only need units designed for lower pressure ranges around 100 psi.

Another essential consideration is the regulator's materials and construction. As noted by the American Society of Mechanical Engineers (ASME), selecting a regulator made from corrosion-resistant materials can significantly extend its lifespan in harsh environments, reducing maintenance costs by approximately 30%. Furthermore, understanding whether a diaphragm or piston-based mechanism best suits your application is key, as each design offers distinct advantages. Diaphragm regulators are often preferred for their sensitivity and precision, while piston models are favored for their robustness in demanding applications. By evaluating these factors, you can choose a pressure regulator valve that effectively meets your operational requirements.

This chart illustrates the key factors to consider when choosing a pressure regulator valve. The data shows the importance of various criteria based on a survey of engineering professionals.

When selecting a pressure regulator valve, understanding the various types available is crucial to meeting your specific needs effectively.

Two primary types of pressure regulator valves are direct acting and pilot operated.

Direct acting valves work efficiently at lower pressures, making them ideal for simple applications, while pilot operated valves are better suited for higher pressure situations, providing improved control and stability.

Assessing the operational requirements of your system will guide you in making the right choice, whether for an air compressor or a more complex HVAC system.

Recent developments highlight the significance of pressure regulating valves in maintaining system efficiency.

For instance, proper selection and installation of such valves can greatly enhance irrigation uniformity in agricultural applications.

Additionally, advancements in hydronic balancing techniques emphasize the importance of these valves in optimizing water distribution in heating and cooling systems of buildings.

As the pressure relief valves market continues to expand, understanding the functional differences and best applications for each type will become increasingly important for professionals across various industries.

When it comes to ensuring optimal performance of pressure regulator valves, proper installation and maintenance are paramount. According to a report by the American Society of Mechanical Engineers (ASME), improper valve installation accounts for approximately 30% of system inefficiencies. It is essential to follow manufacturer specifications closely; for instance, the orientation of the valve can significantly influence its performance. Valves should be installed in a location that allows for easy access, facilitating routine inspections and maintenance checks.

Regular maintenance is equally crucial in sustaining the functionality of pressure regulator valves. A study by the National Institute of Standards and Technology (NIST) highlights that proactive maintenance can extend the life of these components by up to 50%. Key maintenance practices include inspecting for leaks, ensuring that the pressure settings remain within recommended limits, and replacing worn-out parts promptly. It is advisable to establish a maintenance schedule based on the operational demands and environmental conditions of your facility, as this tailored approach can help in detecting potential issues before they lead to significant downtime.

When selecting a pressure regulator valve, many individuals make common mistakes that can lead to inefficiencies and costly errors. One prevalent issue is overlooking the specific pressure requirements of their system. It is crucial to match the regulator's output pressure with the needs of your application; failing to do so may result in inadequate pressure control, affecting the overall performance of your system. Always take the time to consult manufacturer specifications and ensure that the chosen regulator can handle the expected pressure range.

Another frequent mistake is neglecting the size and flow rate capacity of the regulator valve. Choosing a valve that is either too small or not rated for the necessary flow can create bottlenecks, reducing efficiency and potentially causing damage. It’s essential to evaluate the flow rate requirements by considering the entire system's needs, including any peaks in demand. Additionally, factors such as media type and temperature should be taken into account, as they can further influence the valve's performance and compatibility. By avoiding these pitfalls, you can optimize your pressure regulation and enhance the reliability of your system.