When it comes to ensuring the safety and efficiency of pressure systems, choosing the right pressure relief valve (PRV) is paramount. These vital components act as the frontline defense against excessive pressure, preventing potential hazards that could endanger both equipment and personnel. With a plethora of options available in the market today, selecting the most appropriate pressure relief valve requires a clear understanding of the operational environment, the specific requirements of the system, and the regulatory standards that govern their use.

In the year 2025, the advancements in technology and materials have further complicated the decision-making process. It is crucial to consider factors such as valve sizing, media compatibility, and the type of valve operation—whether it is spring-loaded, pilot-operated, or electronic. Each type presents unique advantages and challenges, making it essential for engineers and safety professionals to be well-informed. This guide aims to provide a comprehensive overview to assist you in making informed choices that safeguard your systems while optimizing operational efficiency. Through a detailed examination of the various types of pressure relief valves, this article will equip you with the knowledge necessary to navigate the complexities of this critical component in safety management.

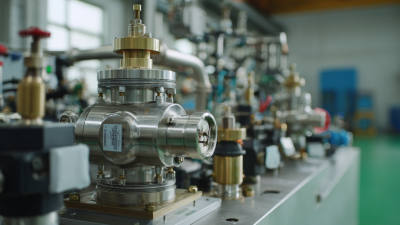

Pressure relief valves (PRVs) play a crucial role in maintaining safety and efficiency in industrial applications. These devices are designed to protect equipment from excessive pressure, which can lead to catastrophic failures, injuries, or even loss of life. In industries such as oil and gas, chemical manufacturing, and power generation, the integrity of pressure relief systems is vital. A properly functioning PRV ensures that pressure levels remain within safe operating limits, thus safeguarding both personnel and equipment.

When selecting a pressure relief valve, it’s essential to consider several factors. Tips for choosing the right valve include evaluating the specific application requirements, such as fluid type and temperature, as well as the pressure rating of the system. Additionally, consult manufacturer guidelines to ensure compatibility and compliance with industry standards. Regular maintenance and testing are equally important; a valve that is not routinely inspected may fail to operate correctly when needed.

Another tip is to assess the potential consequences of valve failure. Understanding the risks associated with pressure relief valves can guide the selection of redundancy measures. For instance, implementing multiple PRVs in critical systems can mitigate the impact of a single valve malfunction. By prioritizing safety and performance, industries can enhance their operational efficiency while protecting their assets and workforce.

| Dimension | Value |

|---|---|

| Set Pressure (psi) | 150 |

| Flow Capacity (SCFM) | 300 |

| Connection Size (inches) | 2 |

| Material | Stainless Steel |

| Temperature Range (°F) | -20 to 400 |

| Body Type | Spring-loaded |

| Testing Standard | ASME Section VIII |

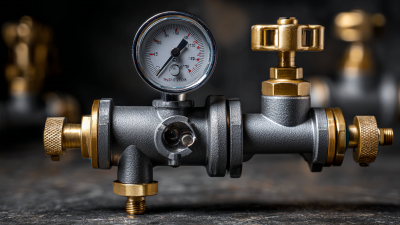

When selecting the right pressure relief valve (PRV), several key factors must be considered to ensure both optimal safety and efficiency. First and foremost, understanding the application context is vital. According to the American Society of Mechanical Engineers (ASME), selecting a PRV that matches the specific conditions of temperature, pressure, and flow rate is essential for preventing catastrophic failures. For instance, in high-temperature applications, materials must be chosen that can withstand severe thermal stresses, reducing the risk of valve failure.

Additionally, the type of fluid being controlled plays a crucial role in the decision-making process. The National Board of Boiler and Pressure Vessel Inspectors reports that incorrect PRV selection for corrosive or non-neutral fluids can lead to accelerated wear and reduced lifespan, ultimately compromising safety. Moreover, the size and capacity of the valve should align with the system's requirements, as undersized PRVs can lead to excessive pressure build-up, while oversized ones may not open at the necessary set pressure, both posing significant safety risks. By carefully evaluating these factors, engineers can ensure that the selected valve operates effectively in their specific environment.

When selecting a pressure relief valve, material selection plays a crucial role in ensuring both performance and longevity. The valve's material must withstand the specific pressure and temperature conditions of its application, as well as resist corrosion and erosion from the process fluids. Materials like stainless steel, brass, and various alloys are often chosen for their strength and resistance to environmental factors. Each material presents unique advantages and drawbacks, making it essential to consider the compatibility of the valve with the operating environment.

Moreover, the impact of material selection extends beyond immediate performance. Long-term durability is influenced by factors such as fatigue resistance and thermal stability. Choosing an appropriate material can substantially reduce maintenance needs and operational interruptions, ultimately enhancing safety and efficiency in system operations. Therefore, thorough analysis of the material's properties in relation to the application conditions ensures that the pressure relief valve will function optimally over its intended lifespan, safeguarding system integrity and reducing the risk of failures.

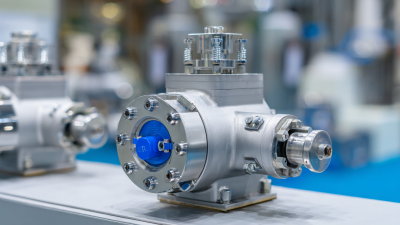

When it comes to ensuring optimal safety and efficiency in industrial processes, the testing and maintenance of pressure relief valves (PRVs) are critical. Best practices dictate that these valves should be tested regularly to confirm their proper operation. A common approach is to perform functional tests at least annually, although the frequency may vary based on specific operational conditions and regulatory requirements. During testing, it is essential to ensure that the set pressure remains accurate and that the valve opens and closes as intended without any leaks.

Maintenance of PRVs involves routine inspections to identify any signs of wear or damage that could hinder performance. Key aspects of maintenance include checking for corrosion, ensuring that the valve is free from obstructions, and verifying the integrity of the sealing surfaces. Implementing a thorough documentation process is also vital; keeping detailed records of testing, maintenance activities, and any repairs made can help in tracking performance trends and ensuring compliance with safety standards. By adhering to these practices, facilities can enhance the reliability of their pressure relief systems and mitigate risks associated with overpressure situations.

When selecting a pressure relief valve (PRV), it is crucial to adhere to established safety standards and regulations to ensure optimal performance and compliance. Organizations such as the American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI) provide guidelines that help manufacturers and users alike make informed decisions. Familiarizing oneself with these standards will significantly enhance the safety and reliability of the valve chosen. Key factors include understanding the design requirements, material specifications, and the testing processes mandated by these organizations.

Additionally, local regulations may impose specific requirements depending on the industry and application. For instance, industries such as oil and gas, chemical processing, and pharmaceuticals often have stringent compliance measures to prevent accidents and ensure public safety. Consulting with experts or regulatory bodies during the selection process can provide valuable insights into the necessary certifications and approvals. This proactive approach not only enhances safety but also contributes to the overall efficiency and longevity of the pressure relief systems in operation.