Choosing the right PVC ball valve for your plumbing system is a critical decision that can significantly impact the efficiency and reliability of water flow in various applications. According to recent industry reports, the global market for PVC ball valves is expected to grow substantially, driven by their affordability, durability, and resistance to corrosion. With an estimated CAGR of 5.3% over the next five years, understanding the specific requirements of your plumbing system becomes imperative. Factors such as pressure ratings, size, and compatibility with different piping materials will play a vital role in ensuring optimal performance. This guide seeks to provide expert insights into selecting the appropriate PVC ball valve, enabling you to make informed choices that align with both industry standards and your individual plumbing needs.

PVC ball valves are essential components in plumbing systems, renowned for their durability and resistance to corrosion. These valves allow for efficient flow control, making them ideal for various applications, from residential plumbing to industrial systems. According to a recent market report by ResearchAndMarkets, the demand for PVC valves is expected to grow at a CAGR of 3.5% through 2026, driven by their cost-effectiveness and reliability in fluid management.

In understanding the basics, it’s crucial to recognize how PVC ball valves operate. They consist of a spherical disc that controls flow, pivoting on an axis. Expert insights highlight that selecting the correct valve size is paramount; improper sizing can lead to inadequate flow rates or increased pressure drops. A study from the American Society of Plumbing Engineers emphasizes that correctly sized valves can optimize system performance by up to 15%, showcasing the value of expert consultation in the selection process. With a variety of options available in terms of pressure ratings and temperature tolerances, ensuring that the chosen PVC ball valve aligns with specific plumbing needs is critical for both efficiency and longevity.

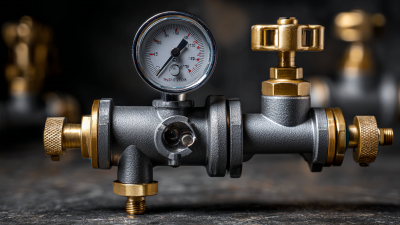

When selecting the right PVC ball valve for your plumbing system, understanding the appropriate size and specifications is crucial. The size of the valve must correlate with the pipeline it connects to; an undersized valve can restrict flow, leading to pressure drops and inefficient operation. Conversely, an oversized valve may cause turbulence and increased wear on the system. To determine the optimum size, consider the diameter of the pipes and any specific requirements dictated by the fluid's flow rate and pressure conditions.

In addition to size, the material specifications of the PVC ball valve play a significant role in its performance. Different applications might require valves that can withstand various levels of temperature and chemical exposure. It is essential to assess the compatibility of the valve materials with the fluids being handled, especially in scenarios involving aggressive chemicals or high temperatures. Furthermore, checking the valve's pressure rating and ensuring it meets or exceeds the system’s operational requirements can prevent issues in the long run, promoting both reliability and longevity in your plumbing system.

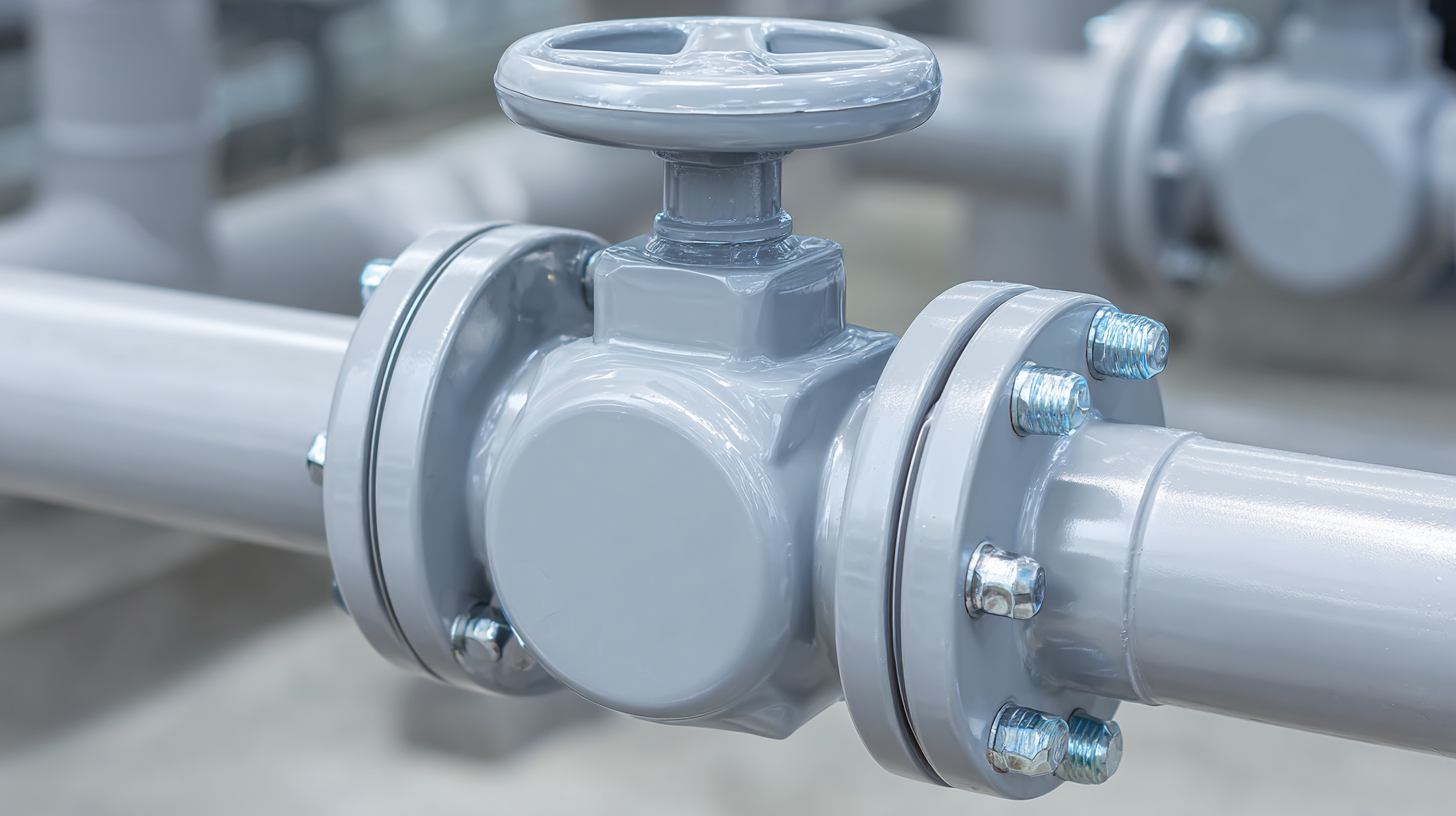

When selecting a PVC ball valve, it's essential to evaluate the various types available to meet your specific plumbing needs. PVC ball valves come in different designs, each tailored to distinct applications, such as residential plumbing, industrial systems, or irrigation. Full-port valves are ideal for high flow and minimal pressure drop, making them excellent for water supply lines. On the other hand, standard-port valves are more compact and cost-effective, suitable for less demanding systems.

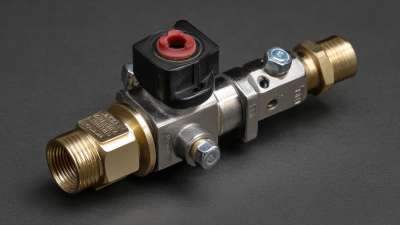

Another critical factor to consider is the valve's connection type. PVC ball valves can feature threaded, socket, or flanged connections, depending on your installation requirements. Threaded valves are easier to install and remove, while socket connections offer a more robust seal suitable for permanent setups. Additionally, assess the valve’s pressure rating and temperature tolerance to ensure it aligns with your plumbing system's specifications. By understanding these differences, you can choose a PVC ball valve that ensures reliable performance and longevity in your plumbing system.

When selecting a PVC ball valve for your plumbing system, prioritizing material quality and durability is crucial. According to a report by the Plastics Pipe Institute, high-quality PVC valves are resistant to corrosion and can withstand pressures of up to 150 PSI, making them ideal for various applications. Choosing a valve manufactured from virgin PVC material not only ensures better performance but also enhances longevity, as recycled materials may compromise structural integrity and lead to early failure.

Furthermore, experts recommend selecting valves that meet ASTM standards for PVC products, such as ASTM D1784, which defines the physical and chemical properties required for high-performance valves. A study from the American Society of Sanitary Engineering highlights that properly rated PVC ball valves can have a service life exceeding 25 years when installed correctly. This underscores the importance of investing in durable materials to minimize future maintenance costs and system downtime. Thus, considering these factors will help ensure your plumbing system operates efficiently and reliably for years to come.

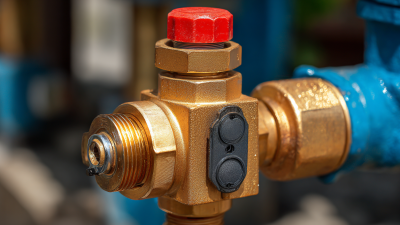

When installing PVC ball valves in your plumbing system, it’s crucial to choose the right fittings and ensure a secure connection. Begin by ensuring that all surfaces are clean and free from debris; this promotes a better seal and prevents leaks. It is often recommended to use PVC solvent cement for joining pipes and fittings, as this creates a strong bond. Be mindful of the valve's orientation; the handle should be easily accessible for operation, ideally positioned in the open/close direction that matches the flow.

Regular maintenance is key to prolonging the life of your PVC ball valves. Inspect them periodically for signs of wear, such as cracks or discoloration. Rotating the handle periodically helps to prevent the valve from seizing due to infrequent use. If leaks occur, ensure that the valve is tightened correctly and consider disassembling it for a thorough cleaning or replacement of worn seals. Following these expert maintenance tips can help ensure reliable performance and longevity of your plumbing system.