In today's rapidly evolving manufacturing landscape, China stands out as a global powerhouse, particularly in the production of high-quality water solenoid valves. The demand for these critical components is increasing, with the global water solenoid valve market projected to reach $3.2 billion by 2028, growing at a CAGR of over 5% from 2021 to 2028, according to a recent industry report. This growth is fueled by expanding applications across various sectors, including irrigation, water treatment, and industrial automation.

As businesses worldwide seek reliable partners to enhance efficiency and ensure optimal performance, China's superior manufacturing capabilities position it as a prime source for the best water solenoid valves. In this blog, we will explore how to leverage China’s manufacturing excellence to secure the most effective solutions for your water handling needs and contribute to your operational success.

China has firmly established itself as a global leader in the manufacturing of water solenoid valves, reflecting its dominance in the industrial valve market. According to recent industry reports, the global industrial valve market is projected to reach significant growth, driven by increasing demand across various sectors, including water and wastewater management, oil and gas, and power generation. China's production capabilities enable it to supply a vast range of valve types, including solenoid valves, which are integral for precise control in automation processes.

Key statistics reveal that the industrial valve market is expected to expand at a CAGR of approximately 5.6% over the next few years, with solenoid valves playing a crucial role given their efficiency and reliability. Moreover, China's manufacturing prowess allows for the integration of advanced technologies and cost-effective production methods, positioning itself as a preferred partner for international customers. The continuous investment in innovation and sustainable practices further solidifies China's status in meeting the evolving needs of global industries.

In recent years, significant advancements in manufacturing techniques have revolutionized the production of water solenoid valves, enhancing their performance and reliability. The integration of automation and precision engineering has enabled manufacturers to produce valves with tighter tolerances and improved responsiveness. According to a report by MarketsandMarkets, the global solenoid valve market is expected to grow from $4.2 billion in 2020 to $6 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.4%. This growth is driven by the demand for automated processes across various industries, including automotive and agriculture.

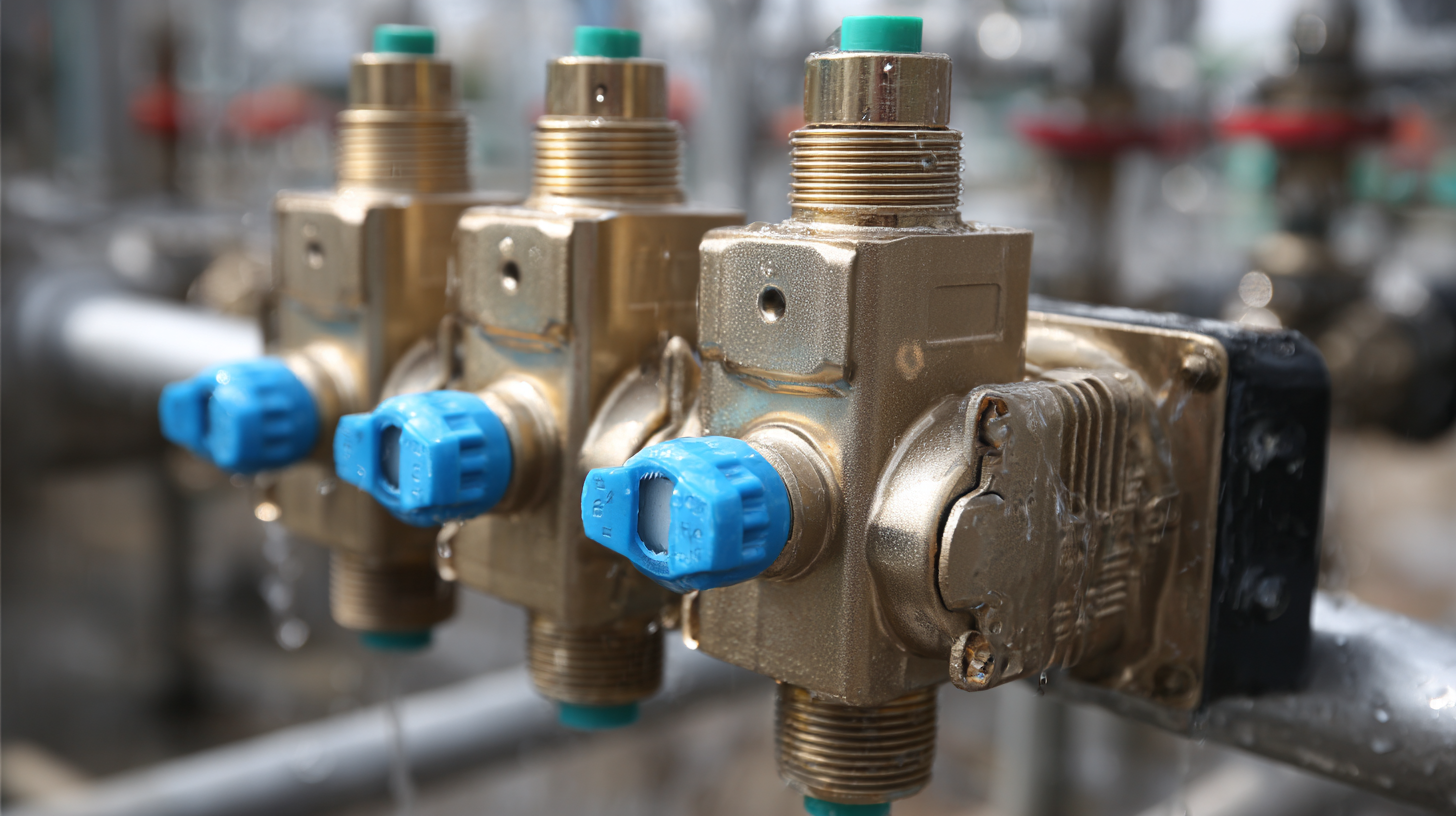

To ensure optimal valve performance, it is essential to stay updated on the latest manufacturing technologies. For instance, employing advanced materials such as stainless steel and specialized plastics can significantly enhance durability and corrosion resistance. Additionally, utilizing simulation software during the design phase can help identify potential issues and optimize valve functionality before production begins.

Tip: When selecting solenoid valves, consider the application-specific requirements such as temperature, pressure ratings, and fluid compatibility. This proactive approach will not only improve the performance of your systems but also contribute to long-term operational efficiency.

China has established itself as a leader in manufacturing water solenoid valves, primarily due to its stringent quality control standards. In the competitive landscape of global markets, Chinese production facilities have implemented rigorous protocols that ensure each product meets international safety and performance specifications. These benchmarks not only foster trust among manufacturers and consumers but also elevate the overall standards within the industry, making Chinese-made solenoid valves a preferred choice worldwide.

Moreover, the integration of advanced technology in production processes enhances quality assurance. Factories utilize automated systems and real-time monitoring to maintain consistency and reduce error rates, demonstrating a commitment to excellence. The collaboration between local manufacturers and international quality certification bodies further underscores the importance of adhering to global standards while catering to diverse market needs. As a result, businesses looking for reliable water solenoid valves find a valuable partner in China's manufacturing sector, where quality control is paramount to success.

China's dominance in the manufacturing of water solenoid valves offers a compelling competitive advantage in the global supply chain. As industries increasingly seek efficiency and reliability, Chinese manufacturers have capitalized on their advanced production techniques and cost-effectiveness. The global solenoid valve market is projected to reach approximately USD 4.91 billion by 2025, with an anticipated compound annual growth rate (CAGR) of 4.5%. This growth showcases the rising demand for high-quality solenoid valves and highlights China's role as a key player in fulfilling this need.

The current landscape of the industrial valve market further reinforces China's superior positioning. With an estimated market size of $95.58 billion by 2024, the increasing capital investment and infrastructural development across various sectors are driving demand. Chinese manufacturers not only meet stringent international standards but also leverage economies of scale, allowing them to offer competitive pricing without compromising on quality. This strategic advantage enables them to serve as essential partners for global companies seeking reliable and efficient water solenoid valve solutions, ensuring success in an ever-evolving marketplace.

| Feature | China's Water Solenoid Valves | Competitors |

|---|---|---|

| Material Quality | High-grade brass and stainless steel | Varies, often lower grade |

| Production Efficiency | High-speed automated processes | Manual processes may linger |

| Cost Competitiveness | Lower production costs, competitive pricing | Generally higher production costs |

| Lead Time | Shorter lead times due to efficiency | Longer lead times |

| Customization Options | Flexible designs available | Limited customization |

| Export Capability | Widespread global partnerships | Local or regional focus |

China has established itself as a leading player in the manufacturing of water solenoid valves, not just because of its high-quality production capabilities but also due to its commitment to sustainability. The country’s manufacturing sector has adopted a range of sustainable practices, including the integration of advanced technologies and energy-efficient processes. According to a report by McKinsey, 85% of manufacturers in China are now implementing green practices, significantly reducing their carbon footprint and enhancing operational efficiency.

One notable trend in the industry is the emphasis on recyclable materials and reduced waste generation. A study published by the China National Resources Recycling Association indicates that the use of recycled materials in the manufacturing of water solenoid valves has increased by 30% over the past five years. This shift not only helps in lowering production costs but also mitigates the environmental impact, aligning with global sustainability goals. Furthermore, with the Chinese government's support for green technology funding, manufacturers can invest in innovations that further enhance their sustainable practices.

In addition, the implementation of these practices has far-reaching implications for global supply chains. According to a report from the World Economic Forum, companies that prioritize sustainability are likely to experience a 15% growth rate compared to those that do not. As global partners seek reliable sources for water solenoid valves, China's manufacturing leaders are not only meeting current demands but also setting industry standards for sustainability in a rapidly evolving market.