In the ever-evolving landscape of industrial applications, ensuring optimal performance is paramount, and the choice of components plays a critical role. One such vital component is the pressure regulator valve, which is essential for maintaining desired pressure levels in various systems. According to a report by MarketsandMarkets, the global pressure regulator market is projected to reach $3.6 billion by 2025, highlighting the growing recognition of the importance of these devices in fields such as oil and gas, pharmaceuticals, and water treatment. As industries continue to prioritize efficiency and safety, selecting the best pressure regulator valves has never been more crucial. This blog aims to explore the seven best pressure regulator valves for 2023, providing insights into their features, applications, and performance metrics to help professionals make informed decisions.

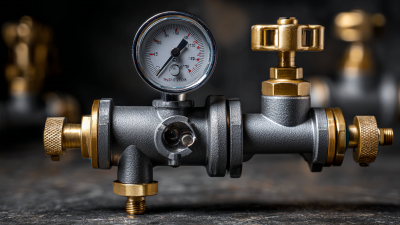

Pressure regulator valves play a crucial role in maintaining consistent pressure within various systems, ensuring optimal performance and safety. These valves automatically adjust output pressure, preventing fluctuations that could lead to equipment damage or inefficient operation. Key features to look for include the valve's accuracy, range, and response time, as these factors significantly influence its effectiveness in managing pressure levels.

Pressure regulator valves play a crucial role in maintaining consistent pressure within various systems, ensuring optimal performance and safety. These valves automatically adjust output pressure, preventing fluctuations that could lead to equipment damage or inefficient operation. Key features to look for include the valve's accuracy, range, and response time, as these factors significantly influence its effectiveness in managing pressure levels.

When selecting a pressure regulator valve, consider the specific application and system requirements. For instance, industrial settings may necessitate high-flow valves capable of handling extreme pressure levels, while residential systems might require smaller, more precise options. It's essential to verify compatibility with the existing piping and equipment to prevent leaks and other potential issues.

Tips: Always consult manufacturer specifications to determine the most suitable pressure regulator valve for your needs. Regular maintenance and testing can also prolong the valve's lifespan, ensuring it performs reliably under varying conditions. Additionally, investing in high-quality regulators can minimize long-term costs associated with replacements and repairs.

When selecting a pressure regulator valve, there are several key factors to consider for optimal performance. First and foremost, it’s essential to identify the specific applications of the valve. Different industries, such as HVAC, automotive, or manufacturing, may demand distinct pressure ranges and flow characteristics. Understanding the operating environment, including temperature and fluid type, is crucial to ensure the valve can handle the conditions without failure.

Another significant consideration is the valve’s material and construction. High-quality materials like stainless steel or brass are often required for durability and corrosion resistance, especially in harsh environments. Additionally, the size and connection type should match the existing piping system to ensure a proper fit and prevent leaks. Finally, pay attention to the valve's response time and accuracy, as these characteristics directly impact the efficiency and stability of the pressure regulation. By evaluating these factors, you can choose a pressure regulator valve that will provide reliable and effective performance, tailored to your specific needs.

When it comes to ensuring optimal performance in various applications, selecting the right pressure regulator valve is crucial. In this review, we explore seven exceptional pressure regulator valves that cater to a range of needs, from industrial settings to home use. Each valve stands out for its unique features, such as adjustable pressure settings, durability, and compatibility with different types of gases and liquids. Whether you are managing HVAC systems, gas pipelines, or agricultural irrigation, these regulators promise to enhance performance and safety.

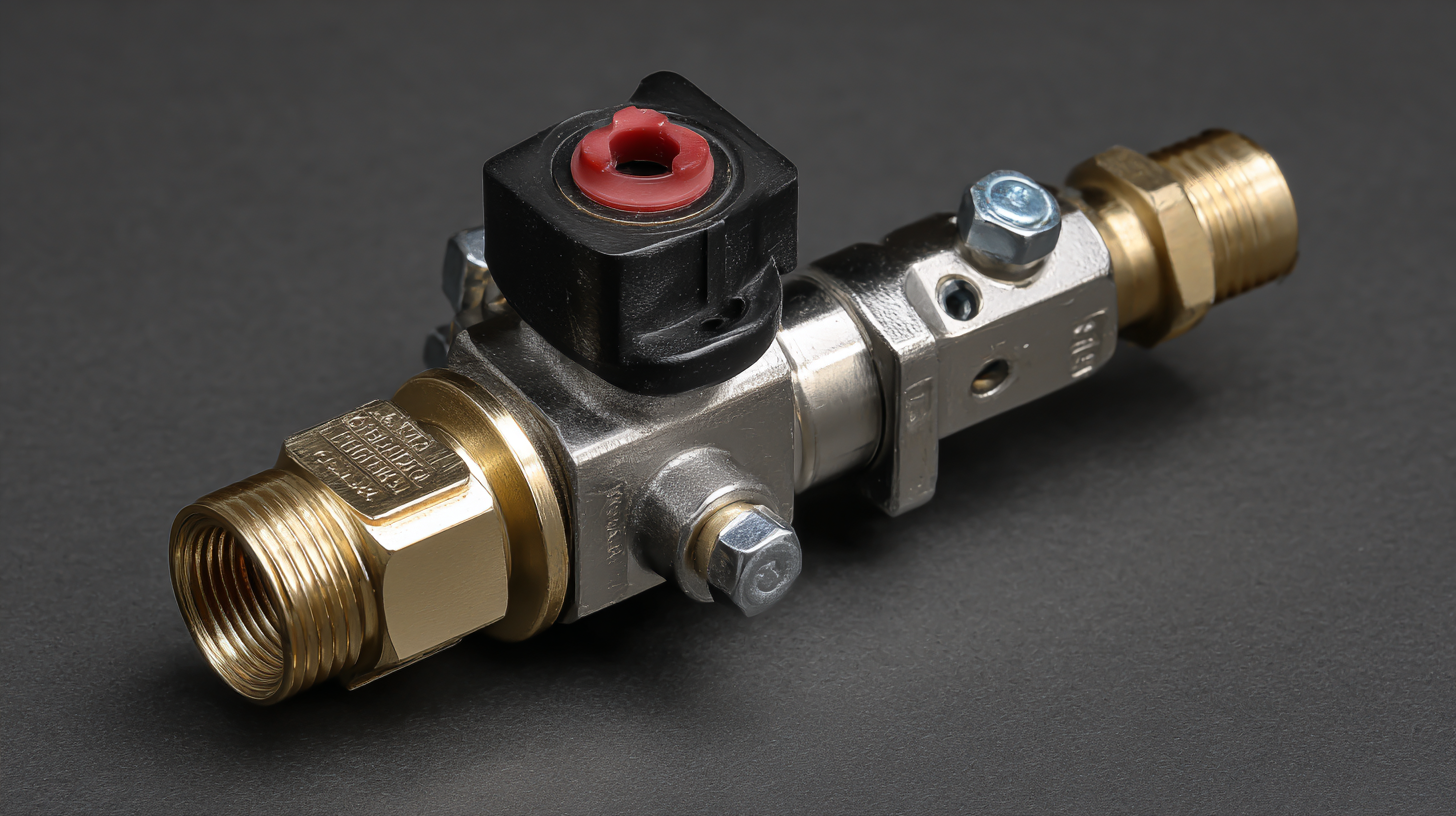

The reviewed valves not only excel in functionality but also provide ease of installation and maintenance. For instance, some models are designed with built-in filtration to prevent contaminants from affecting performance, while others boast compact designs that fit seamlessly into tight spaces. By analyzing the specifications and user feedback, this blog aims to equip you with the knowledge needed to make an informed choice tailored to your specific application requirements. Explore our top picks to discover how these pressure regulator valves can improve efficiency and reliability in your projects.

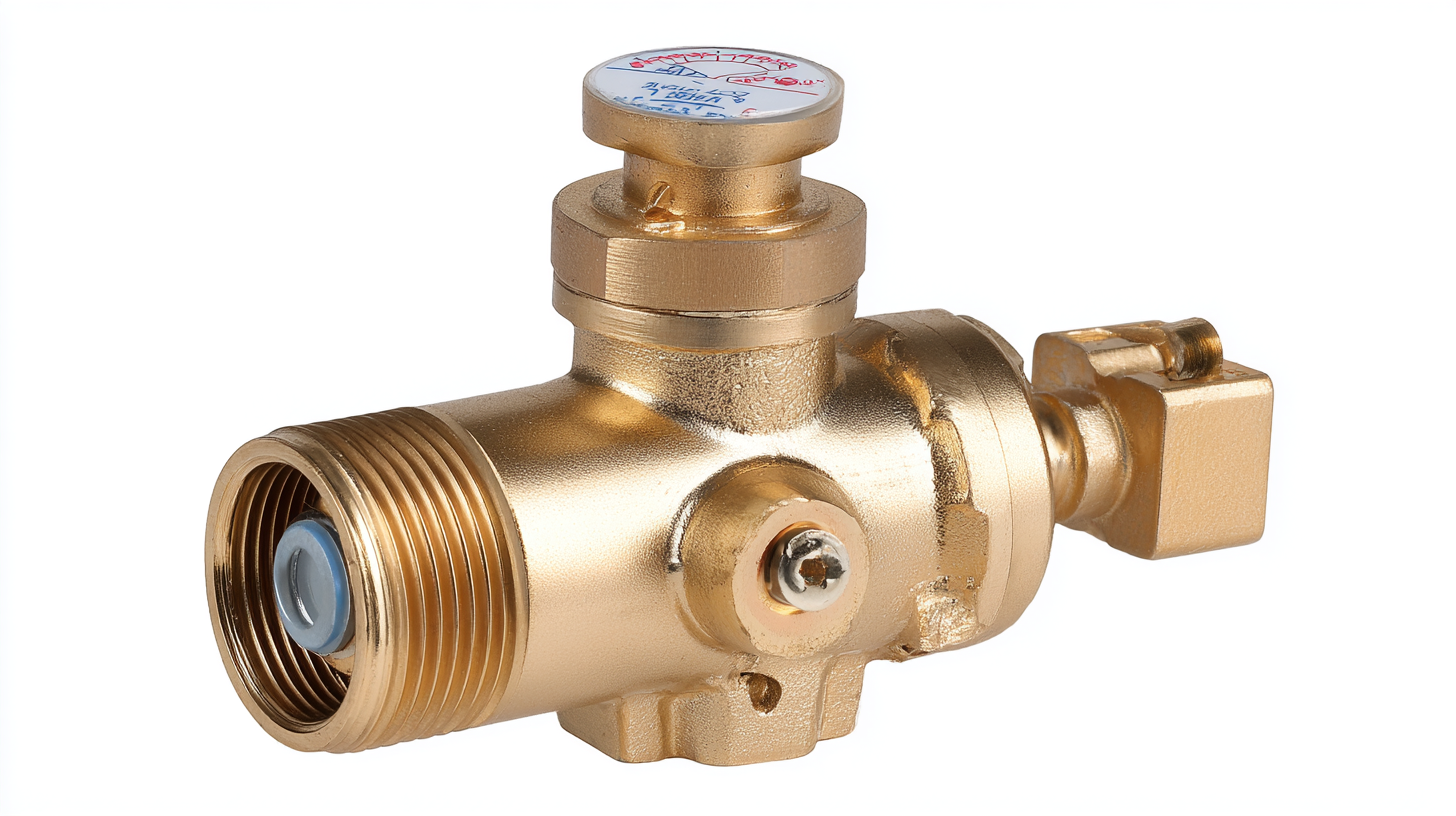

Proper maintenance of pressure regulator valves is essential for ensuring their longevity and optimal performance. Regular inspections can help identify any wear or damage that might affect their efficiency. One important tip is to check for leaks regularly. A small leak can lead to significant pressure drops and increased energy costs. Utilizing a soap solution to detect leaks is an effective method; bubbles will form at the leak site, providing a clear visual cue that maintenance is necessary.

Another key aspect is cleaning the valves periodically to prevent sediment buildup, which can impede performance. It's advisable to remove the valve and clean it with a soft brush and soapy water, ensuring that all parts are free from debris. Make sure to lubricate the moving components according to the manufacturer’s guidelines to reduce friction and wear, contributing to a longer service life. Regular maintenance not only extends the lifespan of your pressure regulator valves but also promotes a safer and more efficient operation overall.

Pressure regulator valves are crucial components in various industries, ensuring that systems operate within safe and efficient pressure levels. However, these valves are not impervious to common issues that can hinder their performance. According to industry reports, approximately 20% of pressure-related failures are attributable to faulty pressure regulator valves, highlighting the importance of proactive maintenance and troubleshooting.

One frequent problem is inconsistent pressure output, which can be caused by clogged filters or faulty diaphragms. Data from the American Society of Mechanical Engineers indicates that routine inspections can identify such issues early, potentially reducing downtime by as much as 30%. Additionally, leaks around the valve can significantly impact system efficiency, leading to increased operational costs. Implementing a regular maintenance schedule that includes checking for leaks and functionality can extend the lifespan of these valves and ensure optimal performance.

Another common issue is the incorrect sizing of pressure regulator valves. A miscalculated pressure requirement can result in inadequate flow or, conversely, excessive pressure spikes. According to a study by the National Institute of Standards and Technology, proper valve sizing can improve system reliability by upwards of 25%. Keeping accurate records of system requirements and valve performance can aid operators in selecting appropriately sized valves and troubleshoot effectively, thus enhancing overall system efficiency.