In the world of plumbing, the choice of valve can significantly impact system efficiency and reliability. Among various types, the ball valve stands out for its robust design and ease of operation. "A high-quality ball valve is essential for ensuring leak-proof connections and optimal flow control in any plumbing application," says Dr. Sarah Thompson, a renowned expert in fluid mechanics. Her insight underscores the growing demand for reliable ball valves across residential, commercial, and industrial settings.

As plumbing systems continue to evolve, so do the technologies behind the ball valve. These valves are not only crucial in regulating flow but also play a vital role in maintenance and longevity of plumbing fixtures. This article will explore the ten best ball valves on the market, highlighting features that make them ideal for achieving both performance and reliability. Understanding these aspects can help homeowners and professionals alike make informed decisions, ensuring their plumbing systems operate flawlessly. Whether you're replacing an old valve or installing a new one, selecting the right ball valve is key to achieving durability and efficiency in plumbing installations.

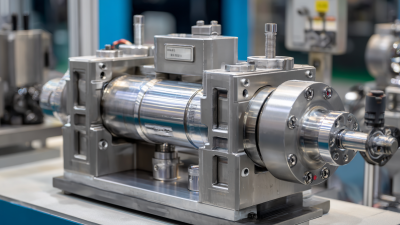

Ball valves are crucial components in plumbing systems, known for their reliability and performance. These valves allow the flow of liquids or gases through a pipe by using a spherical disk, which can rotate to open or close the passage. Their simple design and effective function make them ideal for a variety of applications, from residential plumbing to industrial systems. The tight seal they provide prevents leaks, ensuring that the plumbing system operates efficiently and without wastage.

When selecting a ball valve, consider factors such as material, size, and application requirements. For instance, using brass or stainless steel valves can enhance durability and prevent corrosion, which is vital in maintaining the integrity of the plumbing system.

***Tips:*** Ensure that the valve you choose suits the fluid type and pressure conditions of your plumbing system. Regular maintenance and inspection of ball valves can also prolong their lifespan and maintain optimal performance. Additionally, be mindful of installation orientation; while most ball valves can be installed in various positions, adhering to manufacturer guidelines can enhance functionality.

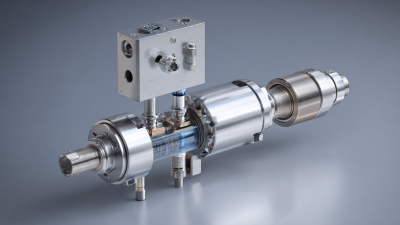

When selecting the best ball valves for plumbing applications, understanding the key characteristics that define high-performance models is crucial. A top-quality ball valve typically features a robust construction, often made from materials such as brass or stainless steel, which ensure durability and resistance to corrosion. The design should also include a reliable sealing mechanism, often involving Teflon or similar materials, that provides a tight shut-off and reduces the risk of leaks. The ability to withstand high pressure and temperature variations is another vital attribute that contributes to overall efficiency and reliability in plumbing systems.

In addition to robust materials and effective sealing, the operational ease of a ball valve plays an important role in performance. A well-designed ball valve should allow for quick and effortless operation, often facilitated by a user-friendly lever or handle. This ensures that the valve can be easily opened or closed, even in tight or awkward spaces. Furthermore, features such as full-bore designs enhance flow rates, minimizing pressure drops across the valve and supporting optimal system performance. By focusing on these core characteristics, users can select ball valves that not only meet their immediate needs but also provide long-lasting reliability and efficiency in their plumbing systems.

This chart illustrates the key performance characteristics of high-quality ball valves suitable for plumbing applications. The values represent a scale from 0 to 100, highlighting the importance of durability, flow rate, pressure rating, temperature range, and material quality in ensuring optimal functionality and reliability.

When selecting the best ball valves for plumbing applications, reliability and efficiency are paramount. According to a report by the International Society of Automation, approximately 40% of valve failures can be traced back to improper installation or the use of sub-standard materials. This emphasizes the importance of investing in high-quality ball valves, as they can significantly reduce maintenance costs and downtime associated with valve failures. Reliable ball valves are designed to withstand high pressure and temperature variations, ensuring optimal performance over their lifespan.

Efficiency in plumbing systems also hinges on the precision of flow control, and ball valves are renowned for their ability to provide quick and reliable shut-off capabilities. The American Society of Mechanical Engineers (ASME) states that the use of high-quality ball valves can improve system efficiency by up to 25%, minimizing wastage and energy loss. Furthermore, advancements in design, such as the introduction of soft-seated ball valves, enhance sealing performance, providing leak-free operation that is crucial for both residential and industrial applications. Therefore, choosing top-tier ball valves not only ensures long-term reliability but also promotes overall system efficiency, making them an essential component in modern plumbing systems.

When selecting a ball valve for plumbing applications, several critical factors should be considered to ensure optimal performance and reliability. One of the primary considerations is the valve's material. Common materials such as brass, stainless steel, and PVC each have their unique advantages depending on the application environment. For instance, stainless steel offers excellent corrosion resistance, making it suitable for systems handling aggressive fluids, while PVC is lightweight and ideal for low-pressure applications.

Another essential factor is the valve size and connection type, which must match the existing plumbing system to avoid leaks and ensure effective flow control. Additionally, the valve's pressure and temperature ratings should align with the system's operational requirements to prevent failures. It's also important to consider the ease of operation and installation; a valve that is user-friendly can save time and reduce the risk of errors during installation. Finally, reviewing the valve's certification and compliance with industry standards can provide assurance of its reliability and performance in your specific plumbing application.

| Valve Size | Material | Pressure Rating (PSI) | Temperature Rating (°F) | Connection Type | Features |

|---|---|---|---|---|---|

| 1/2 inch | Brass | 600 | 200 | Female/Female | Lead Free, Full Port |

| 3/4 inch | Stainless Steel | 800 | 250 | Male/Female | Corrosion Resistant, Full Port |

| 1 inch | PVC | 150 | 140 | Socket Weld | Chemical Resistant, Lightweight |

| 1 1/4 inch | Bronze | 600 | 180 | Threaded | Versatile, Easy Installation |

| 1 1/2 inch | CPVC | 200 | 180 | Socket Weld | UV Resistant, Lightweight |

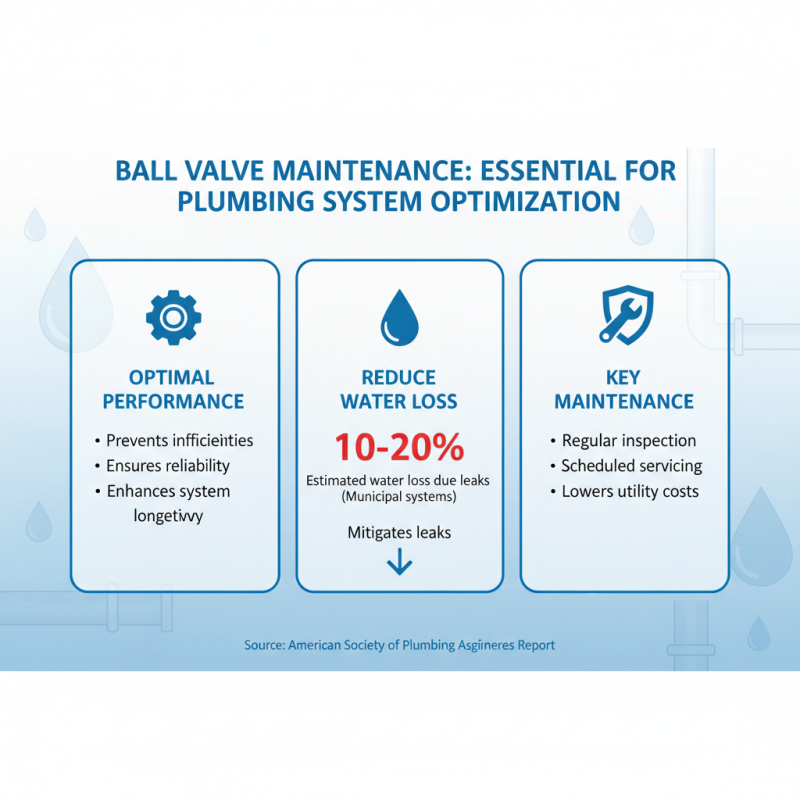

Proper maintenance of ball valves is essential for ensuring optimal performance and reliability in plumbing systems. According to a report by the American Society of Plumbing Engineers, failure to maintain valves can lead to significant inefficiencies, with leaks contributing to an estimated 10-20% of total water loss in municipal systems. Regular inspection and maintenance can mitigate these losses, enhancing system longevity and reducing water utility costs.

Routine maintenance tips include checking for leaks and monitoring valve operation. It is recommended to exercise the valve periodically to prevent seizing, especially in environments with fluctuating temperatures or high moisture levels. Furthermore, cleaning the valve seat and body can prevent the buildup of debris that could hinder performance. A study published in the Journal of Water Resource Management indicates that the implementation of systematic maintenance schedules leads to a 25% increase in overall system efficiency. Using lubricants specifically designed for plumbing applications can also aid in maintaining smooth valve operation, reducing wear and tear over time. By prioritizing these maintenance practices, plumbing professionals can significantly extend the lifespan and reliability of ball valves in their systems.